Jan 12, 2026

In many industrial sites, solenoid valve noise in high-pressure water systems is a common concern. Engineers often report sharp whistling sounds or continuous vibration during valve operation. These noises are not merely acoustic issues—they often indicate underlying fluid dynamic problems that can affect valve reliability.

High-pressure water systems typically operate with high flow velocity and significant pressure differential. When a solenoid valve opens, water must pass through a relatively small orifice within a very short time, creating sudden changes in flow conditions.

The higher the system pressure and the smaller the valve size, the more pronounced these effects become. In many cases, the operating conditions push the valve close to its design limits.

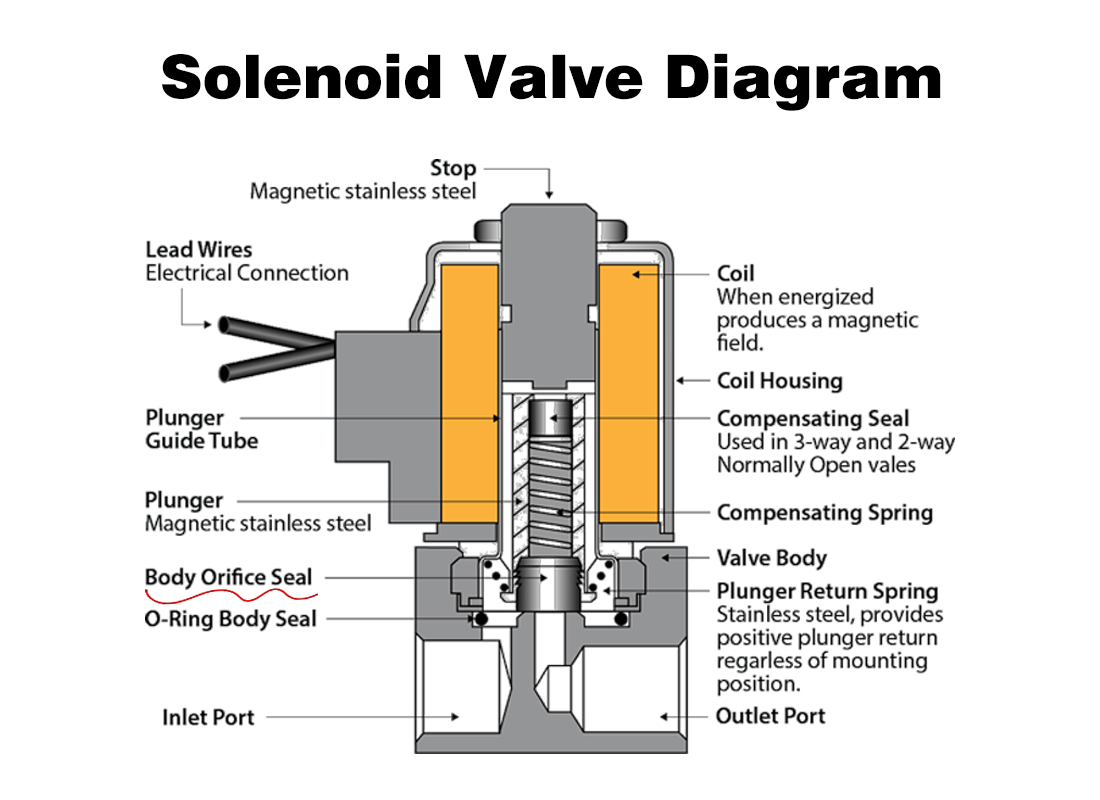

As water passes through the valve orifice, local velocity increases sharply. When velocity exceeds a certain threshold, laminar flow transitions into turbulent flow. Turbulence generates irregular vortices that repeatedly impact the valve core and seat surfaces.

These rapid pressure fluctuations are released as vibration and sound energy, which we perceive as noise. Under large pressure drops, this phenomenon can persist even when the valve is fully open.

The valve core structure plays a crucial role in how water flows through the solenoid valve. Direct-acting solenoid valves, with short stroke and fast response, are particularly sensitive to hydraulic forces in high-pressure water applications.

Uneven fluid forces during opening can cause micro-oscillation of the valve core. Combined with high-frequency water impact, this oscillation may develop into continuous vibration noise.

In many noisy installations, the root cause is not valve failure but improper orifice sizing. When the orifice is too small for the required flow rate, water is forced through a restricted passage, significantly increasing local velocity.

This condition intensifies turbulence, accelerates erosion of the valve seat, and produces audible noise. In many cases, noise is the earliest warning sign before leakage or performance degradation occurs.

From an engineering perspective, noise reflects energy imbalance inside the valve. Persistent vibration subjects valve guides, springs, and sealing elements to additional cyclic stress.

If left unaddressed, noise-related vibration can lead to unstable operation, delayed response, and reduced service life of both the solenoid valve and the piping system.

In practice, engineers often address noise by optimizing both system design and valve selection. Reducing pressure drop across the valve, installing pressure regulators, or adding buffer volumes can stabilize flow conditions.

At the selection stage, choosing a solenoid valve with a suitable orifice size and valve core design for high-pressure water service is far more effective than attempting to suppress noise after installation.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap