Jan 08, 2026

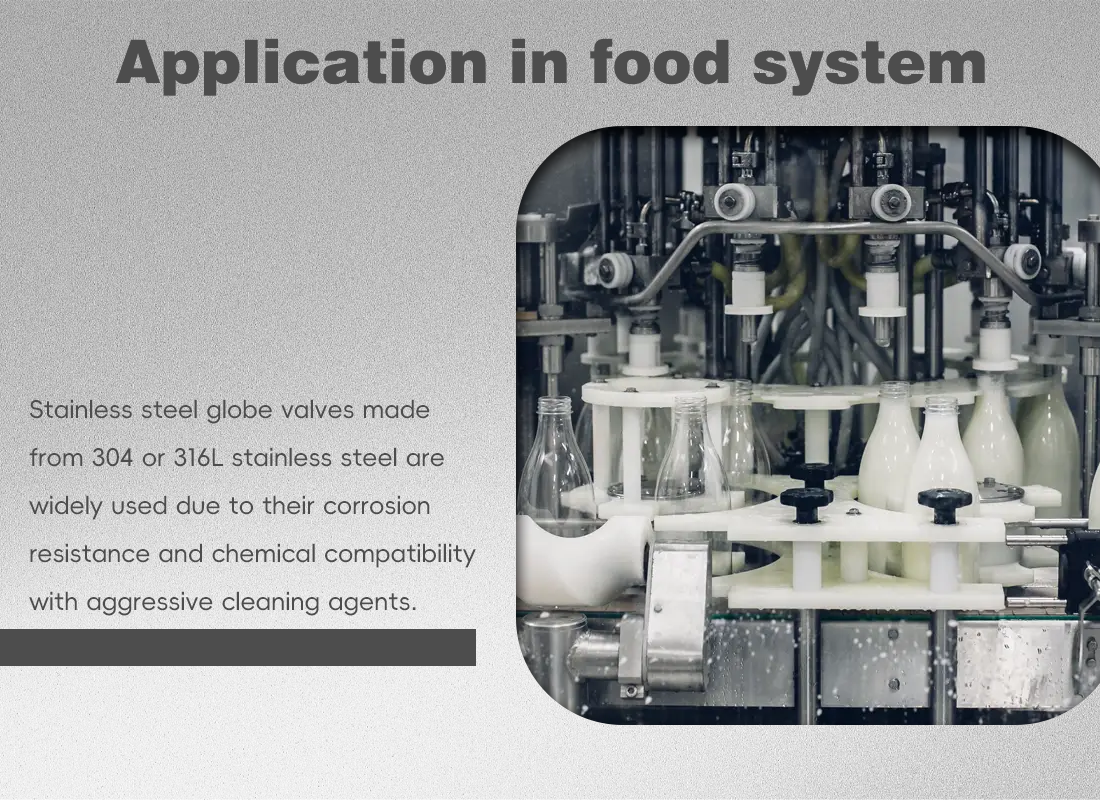

In food and pharmaceutical processing plants, valves rarely attract attention—until hygiene issues arise. For engineers, the real challenge is not pressure rating or flow capacity, but cleanability, material safety, and long-term reliability under repeated sterilization. This is where stainless steel globe valves demonstrate their value.

Food and pharmaceutical pipelines handle sensitive media such as dairy products, purified water, or active pharmaceutical ingredients. Any internal cavity or surface defect can become a contamination risk.

For this reason, stainless steel globe valves made from 304 or 316L stainless steel are widely used due to their corrosion resistance and chemical compatibility with aggressive cleaning agents.

In practice, surface finish plays a greater role than material grade alone. Poor internal polishing can create micro-dead zones where residues accumulate.

Most food grade globe valves specify an internal roughness of Ra ≤ 0.8 μm, while pharmaceutical systems often demand even smoother surfaces. Electropolished finishes reduce adhesion and allow CIP fluids to wash internal cavities more effectively.

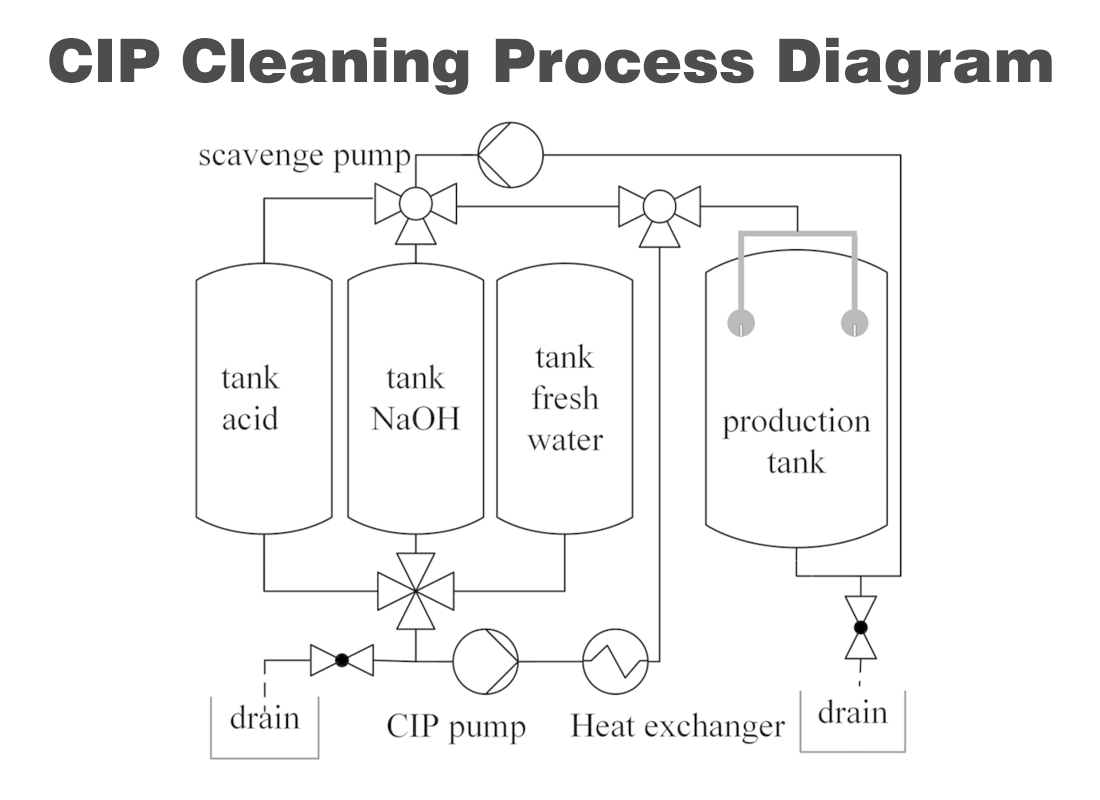

CIP and SIP cycles expose valves to repeated thermal stress. Steam and hot cleaning solutions expand materials and challenge sealing integrity over time.

Unlike soft-seated valves, the axial force distribution of a globe valve disc and seat remains more balanced during thermal expansion. This makes globe valves particularly reliable in high temperature CIP SIP environments.

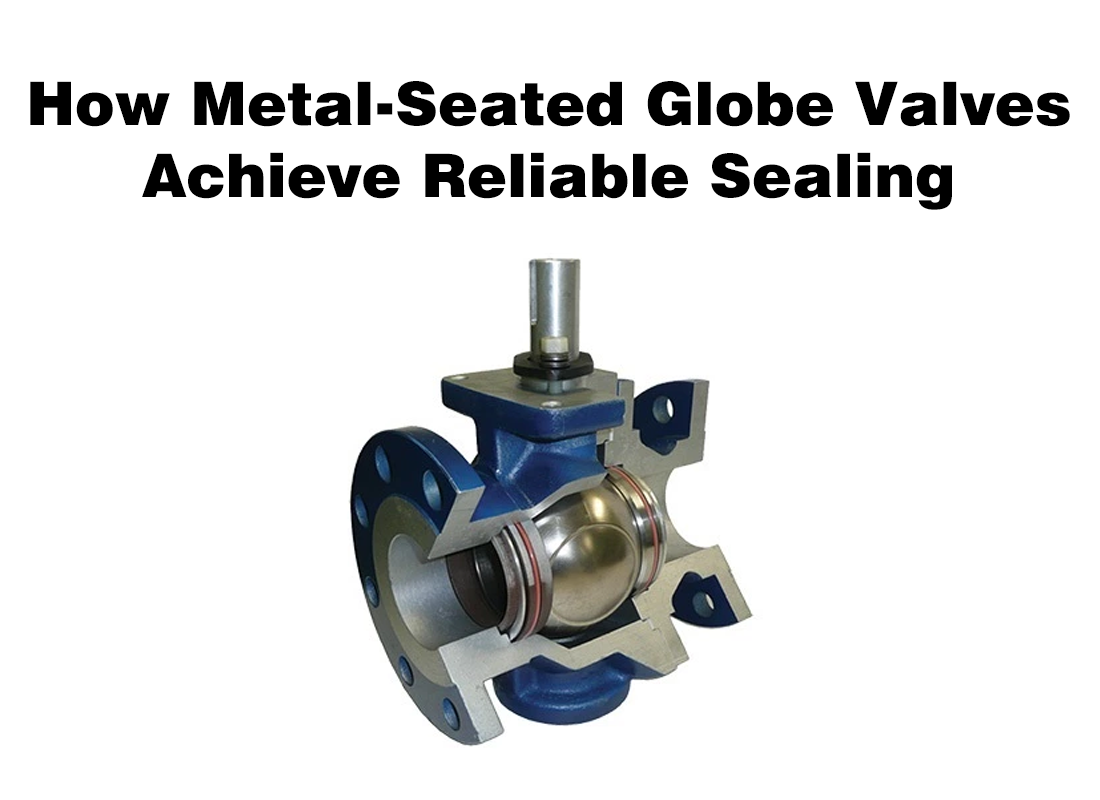

During steam sterilization at 120–150°C, sealing materials age rapidly. Engineers often combine PTFE, reinforced PTFE, or metal-assisted seals with stainless steel seats to maintain performance.

The linear motion of the globe valve disc avoids rotational wear, helping seals last longer in frequent sterilization cycles.

Although globe valves are not full-bore designs, their predictable internal flow path is an advantage in hygienic systems.

The fixed throttling zone created by the disc movement allows CIP validation procedures to consistently verify cleaning effectiveness—one reason globe valves are often accepted in hygienic valve applications.

Regulated industries demand not only performance but inspectability. Stainless steel globe valves feature accessible internal components, allowing periodic inspection of seats, discs, and seals.

This maintainability helps preserve hygienic standards over years of operation, reducing the need for complete valve replacement.

Ultimately, stainless steel globe valves are selected not because they are the cheapest option, but because they balance cleanability, thermal stability, and regulatory confidence.

In systems requiring frequent CIP and SIP under strict audit conditions, this balance delivers long-term operational security.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Jan 08, 2026 Blog

Why Globe Valves Cannot Fully Replace Ball Valves

FOKCA ©1998-2025 All Rights Reserved Sitemap