Jan 08, 2026

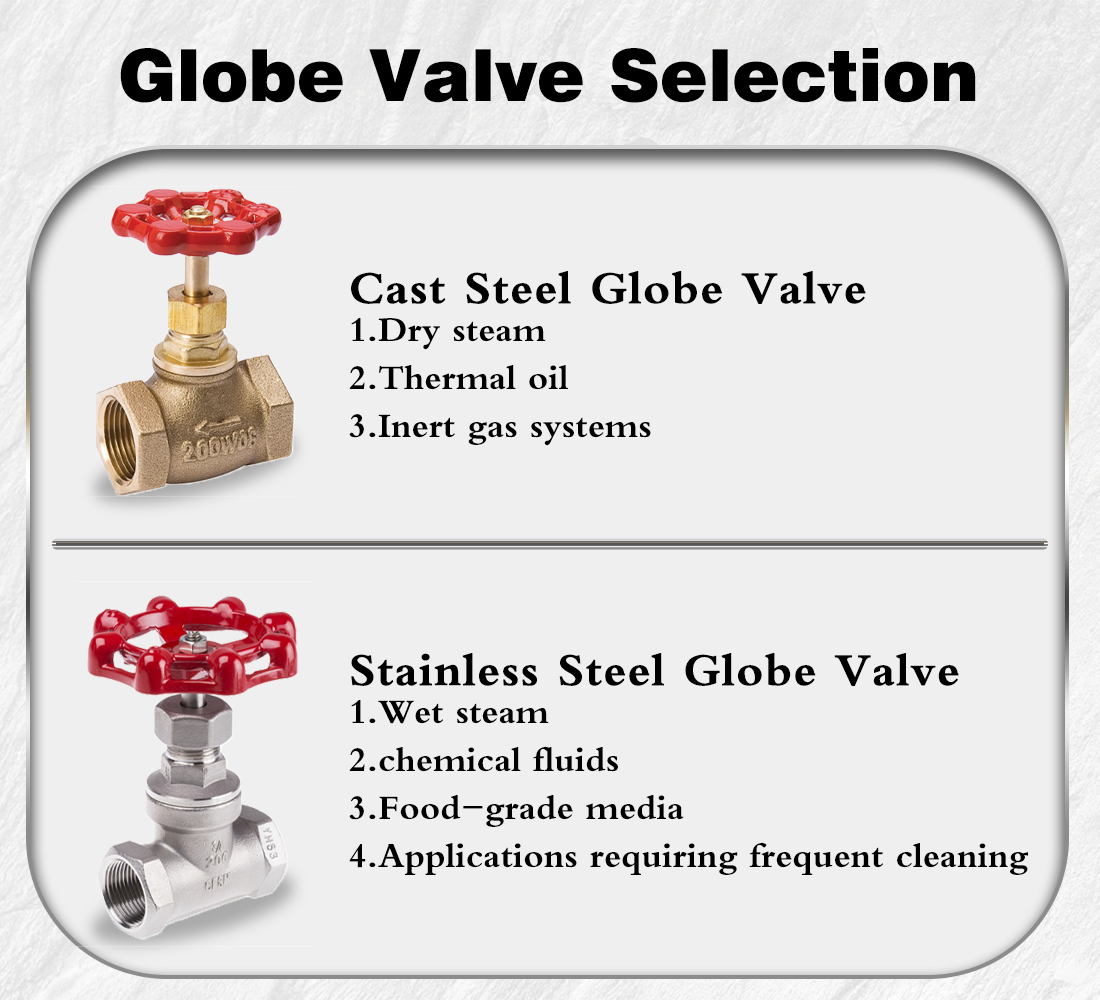

In industrial valve selection, engineers often face a practical dilemma: should a globe valve be made of cast steel or stainless steel?

Although the structure may look similar, material choice has a direct impact on corrosion resistance, service life, and maintenance cost over time.

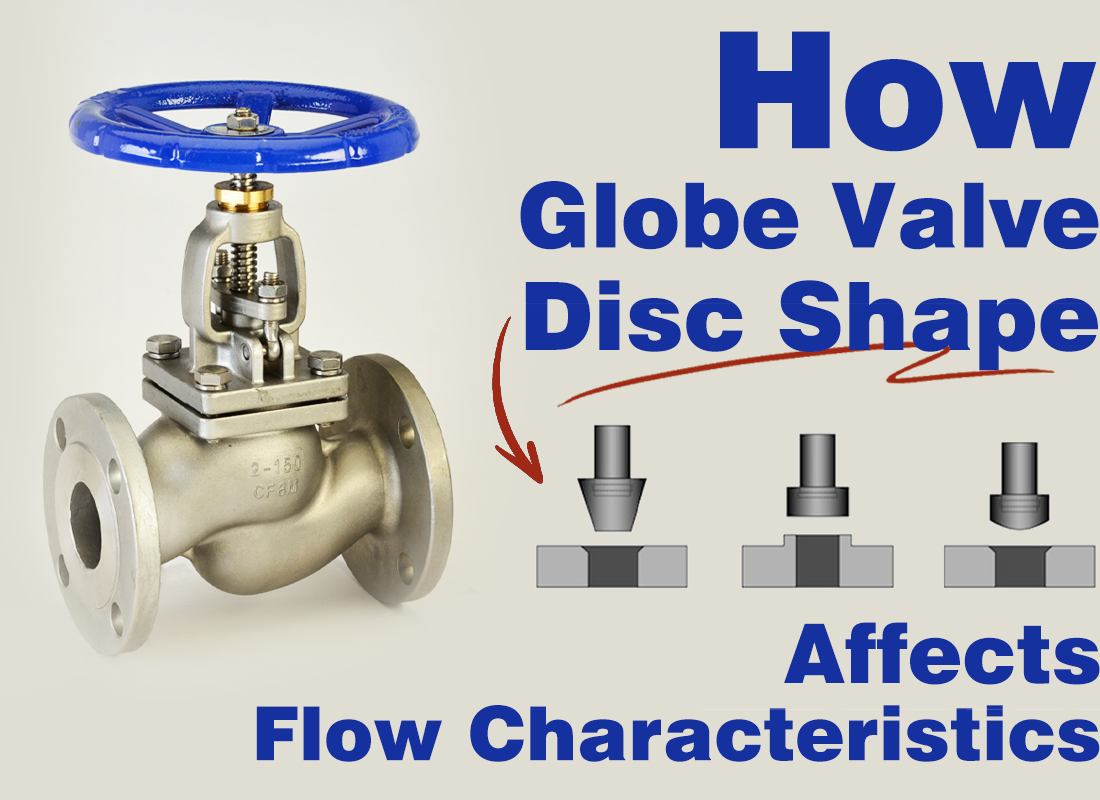

A globe valve is rarely just an on-off component. In most systems, it is used for flow regulation, throttling, and frequent operation. The valve body must withstand internal pressure while remaining stable under temperature changes and media exposure.

In clean and closed-loop systems, engineers tend to prioritize mechanical strength and cost efficiency. In contrast, chemical, food, and pharmaceutical applications place greater emphasis on corrosion resistance and hygiene performance.

| Item | Cast Steel Globe Valve | Stainless Steel Globe Valve |

|---|---|---|

| Typical material | WCB, WC6, WC9 | 304, 316, 316L |

| Mechanical strength | High, suitable for high pressure | High, slightly lower than cast steel |

| Corrosion resistance | Moderate | Excellent |

| High-temperature performance | Good | Good |

| Resistance to wet steam | Limited | Strong |

| Suitability for chemical media | Limited | Very suitable |

| Surface finish | Standard industrial finish | Smooth, easy to clean |

| Service life | Medium | Long |

| Maintenance frequency | Higher in corrosive media | Lower |

| Initial cost | Lower | Higher |

| Typical applications | Steam, thermal oil, inert gas | Chemical, food, pharmaceutical |

Cast steel globe valves are widely used in power generation, petrochemical, and utility applications. Their primary advantage lies in high mechanical strength and reliable pressure resistance, making them suitable for high-pressure steam and thermal oil systems.

From a cost perspective, cast steel offers excellent value for large-diameter valves and large-scale projects. When the medium is clean and non-corrosive, cast steel globe valves can provide long-term stable performance.

However, cast steel has limited corrosion resistance. In the presence of moisture, acidic gases, or chemical media, internal corrosion and seat damage can occur more quickly, increasing maintenance requirements.

The key advantage of stainless steel globe valves is their ability to handle aggressive or hygienic media. Common grades such as 304, 316, and 316L stainless steel perform well in wet, chemical, and mildly corrosive environments.

In food and pharmaceutical systems, valves are often exposed to CIP and SIP cleaning cycles with high-temperature steam. Stainless steel maintains dimensional stability and sealing performance under these conditions, reducing wear on seats and discs.

Over time, stainless steel globe valves typically offer longer service life and fewer unplanned shutdowns, especially in automated production lines.

In terms of strength, cast steel and stainless steel serve different priorities. Cast steel excels in structural rigidity for high-pressure designs, while stainless steel performs better in resistance to pitting and crevice corrosion.

Service life is highly dependent on the operating medium. Clean media favor cast steel, while corrosive or frequently cleaned systems benefit from stainless steel.

Maintenance cost is often underestimated. Although stainless steel valves have a higher initial price, their lower corrosion risk and stable sealing surfaces often reduce long-term maintenance expenses.

For dry steam, thermal oil, or inert gas systems, cast steel globe valves are a proven and economical choice.

For wet steam, chemical fluids, food-grade media, or applications requiring frequent cleaning, stainless steel globe valves provide higher reliability.

In many projects, engineers adopt a hybrid approach, using stainless steel valves at critical points and cast steel valves elsewhere to balance performance and budget.

Valve selection should be based on operating conditions, maintenance capability, and risk tolerance—not material cost alone. As a control-oriented valve, the stability of a globe valve directly affects process accuracy and system uptime.

Understanding the differences between cast steel and stainless steel in terms of strength, corrosion resistance, service life, and maintenance allows engineers to make informed decisions and avoid unnecessary compromises.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Jan 08, 2026 Blog

Why Globe Valves Cannot Fully Replace Ball Valves

FOKCA ©1998-2025 All Rights Reserved Sitemap