Jan 07, 2026

In real-world engineering applications, many automation systems encounter a seemingly contradictory issue during commissioning: the control valve is designed for equal percentage control, yet at small openings the flow fluctuates sharply and becomes difficult to stabilize. In most cases, this so-called “inaccurate equal percentage control” is not caused by the control system or actuator, but by a mismatch between the globe valve disc shape and the actual operating conditions.

Globe valves are widely recognized for their throttling capability. However, what truly defines their flow behavior is not the valve type itself, but the geometry of the valve disc, the stem travel, and how the effective flow area changes during opening. Understanding how disc shape influences the flow curve is a critical—but often overlooked—step in proper valve selection.

In a globe valve, the disc moves in a linear motion along the valve stem. The throttling gap formed between the disc and the seat determines flow velocity and pressure drop. Different disc profiles create very different effective flow areas at the same stroke position, resulting in distinct flow characteristics.

In high-pressure steam systems, thermal oil circuits, or precision flow control applications, fluid density and velocity already change significantly with operating conditions. If the disc shape does not provide a predictable relationship between stroke and flow, the system is more likely to experience hunting, noise, vibration, or accelerated erosion. In essence, the disc shape is the physical mechanism that defines the valve’s flow curve.

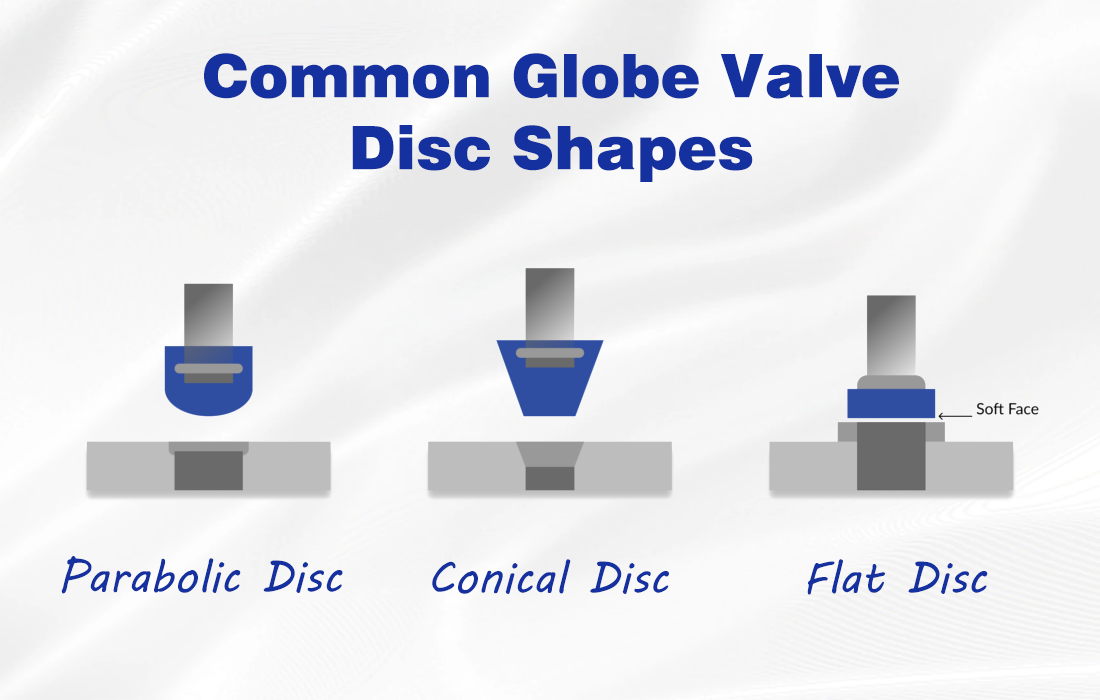

The conical disc is one of the most commonly used designs. At small openings, the increase in flow area is gradual, while at larger strokes the flow rises more rapidly. This behavior closely matches an equal percentage flow characteristic, making it suitable for control loops that require stable regulation at low flow rates.

In steam applications and chemical process control, a conical disc helps prevent sudden flow surges when the valve begins to open. This improves controllability and reduces system instability. However, the trade-off is a relatively higher pressure drop, which must be considered in energy-sensitive systems.

Flat disc designs are mechanically simple and cost-effective, but their flow behavior tends toward a quick opening characteristic. Even a small stem movement can result in a significant increase in flow, making this design more suitable for on/off service rather than precise modulation.

When flat disc globe valves are used in systems that operate for long periods at small openings, engineers often observe excessive sensitivity, overshoot, and unstable control. This is a common root cause of “poor adjustability” in many industrial installations.

Parabolic discs are engineered with a curved profile that produces a more proportional relationship between stem travel and flow rate. This design closely approximates a linear flow characteristic, which simplifies tuning in many control systems.

In laboratory equipment, dosing systems, and low-flow liquid control applications, parabolic discs help reduce control complexity and improve repeatability. They are particularly effective when consistent response across the full stroke range is required.

In theory, equal percentage flow characteristics assume a constant pressure drop across the valve. In real piping systems, however, the pressure differential changes with flow rate. If the disc geometry is already highly sensitive at small openings, these pressure variations amplify non-linear behavior.

For example, in high-temperature steam systems, steam density varies significantly with pressure. An unsuitable disc shape may cause noticeable flow oscillation even when the control signal remains stable. This is why experienced engineers evaluate not only the nominal control characteristic, but also whether the disc profile matches the actual pressure and flow conditions.

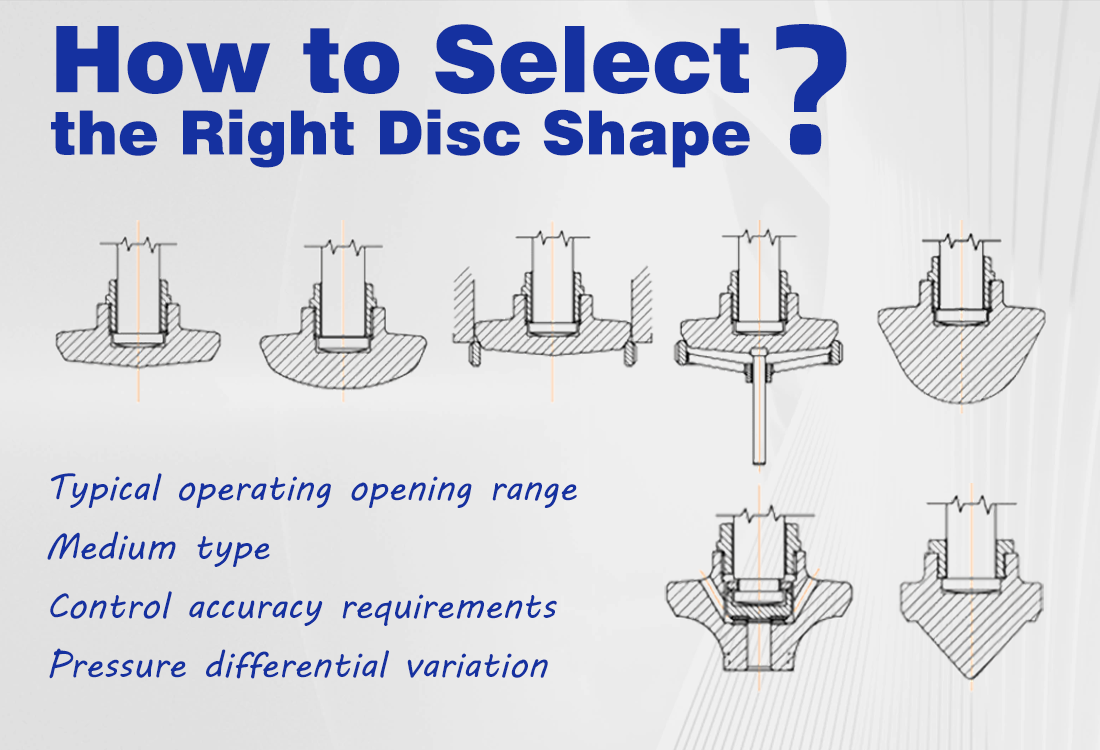

From an engineering perspective, selecting the appropriate globe valve disc shape involves evaluating several key factors:

Typical operating opening range: For valves operating mainly between 10% and 30% open, conical or parabolic discs are preferred

Medium type: Steam and gas applications prioritize stability and pressure drop control, while liquids often favor linear response

Control accuracy requirements: Precision control systems should avoid quick-opening disc designs

Pressure differential variation: The greater the pressure fluctuation, the more important a smooth and predictable flow curve becomes

Ultimately, the advantage of a globe valve lies not only in its ability to regulate flow, but in how disc geometry transforms valve movement into stable, predictable control behavior. Selecting the right disc shape is a fundamental step toward achieving reliable performance in demanding industrial systems.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap