Jan 07, 2026

In high-temperature and high-pressure applications such as steam systems, thermal oil circuits, and petrochemical plants, sealing performance is often the first limitation encountered in valve operation. While soft-seated valves perform well under moderate conditions, their limitations become evident as temperature and pressure increase.

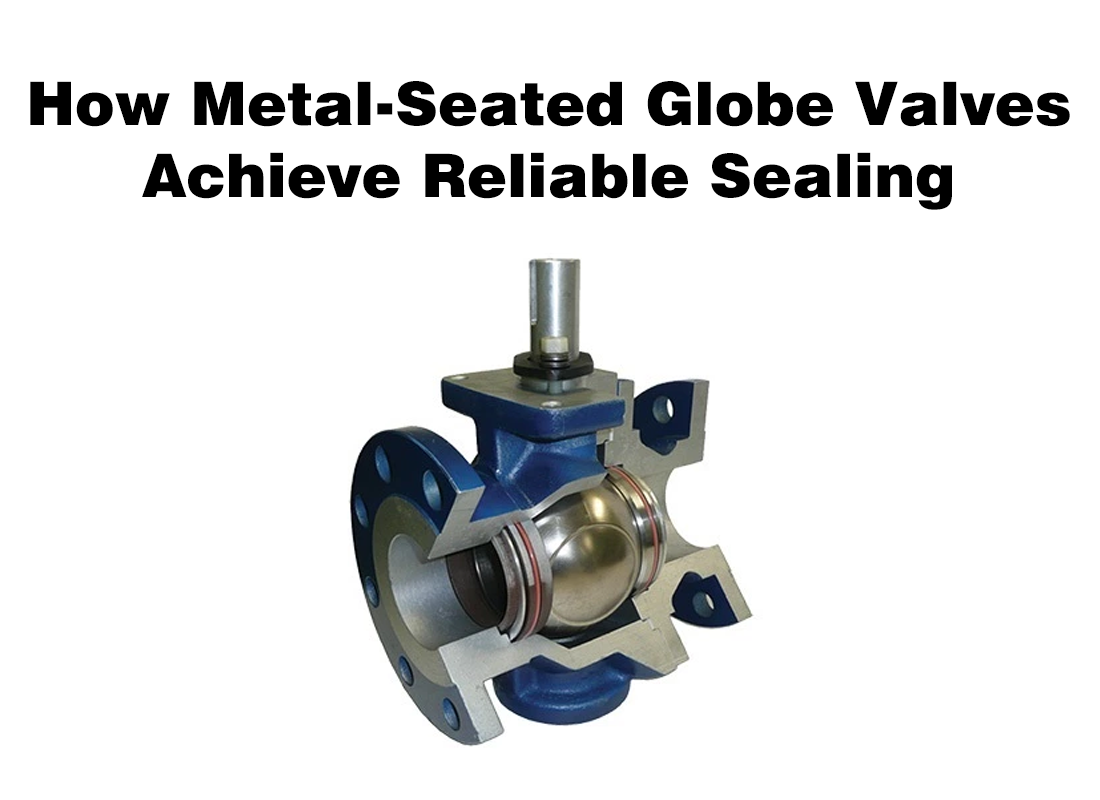

This is why metal seated globe valves are widely used in demanding industrial environments. Instead of relying on elastomeric materials, they achieve sealing through precise metal-to-metal sealing and structural force design.

Soft seals offer low closing torque and excellent initial tightness, but they suffer from thermal aging, deformation, and extrusion under severe conditions. Materials such as PTFE or rubber gradually lose elasticity at elevated temperatures, leading to permanent leakage.

In continuous-duty systems, even without visible damage, soft-seated valves often develop micro-leakage due to material degradation. This makes them unsuitable for long-term service in high-temperature or high-pressure environments.

A metal seated globe valve relies on direct contact between the valve disc and the valve seat, typically made from hardened stainless steel or alloy materials. Surface hardening or hardfacing improves wear resistance and maintains sealing integrity.

When the valve closes, axial force applied through the valve stem generates high contact stress at the sealing interface. Unlike soft seals, sealing performance depends on contact pressure concentration, not material elasticity.

One of the most important advantages of globe valves in high-pressure service is their self-sealing effect. As system pressure increases, fluid pressure acts on the valve disc, pushing it more firmly against the metal seat.

This pressure-assisted sealing mechanism enhances tightness under operating conditions. In properly designed valves, higher pressure leads to improved sealing rather than increased leakage risk. This characteristic is especially valuable in high-pressure steam valves and industrial control valves.

Because metal seals do not soften or degrade with temperature, their sealing performance remains consistent during thermal cycling. Globe valve geometry ensures uniform disc loading, reducing uneven wear and erosion at the sealing surface.

This makes metal seated globe valves particularly suitable for high temperature valve applications, where both flow regulation and sealing reliability are required.

When selecting a metal seated globe valve, engineers should evaluate:

◆ Compatibility of seat and disc materials with temperature and corrosion conditions

◆ Sealing surface finish and hardfacing quality

◆ Structural design that promotes pressure-assisted sealing

◆ Balance between throttling performance and sealing durability

For high-temperature and high-pressure systems, metal seated globe valves provide a sealing solution based on mechanical integrity and force balance, ensuring long-term operational reliability.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap