Jan 07, 2026

In real industrial projects, valve selection is rarely based on datasheets alone. Engineers often face limited installation space, complex piping routes, and long-term maintenance concerns. Under these constraints, the structural differences between straight pattern and angle pattern globe valves become highly relevant.

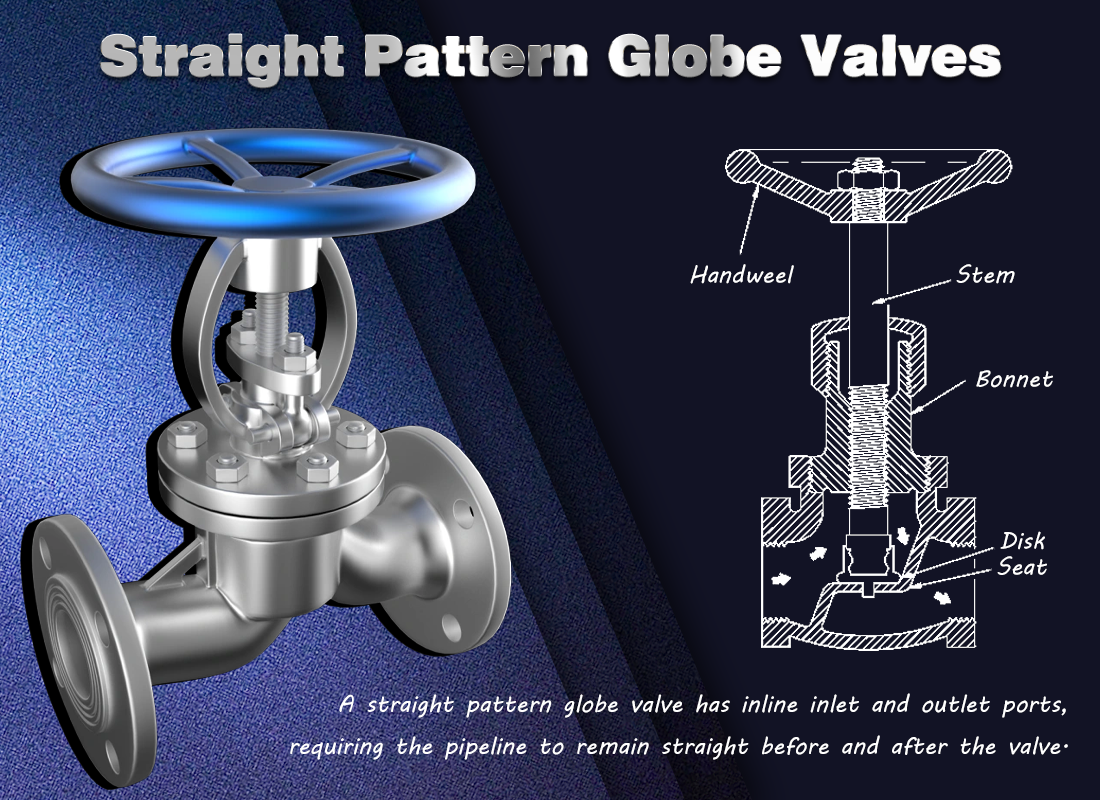

A straight pattern globe valve has inline inlet and outlet ports, requiring the pipeline to remain straight before and after the valve. When space allows, this layout is simple and predictable, making installation and flow analysis straightforward.

However, in compact plants or skid-mounted systems, pipelines often need to change direction within a short distance. Using a straight pattern valve in such cases usually means adding extra elbows, increasing installation time and introducing additional potential leak points.

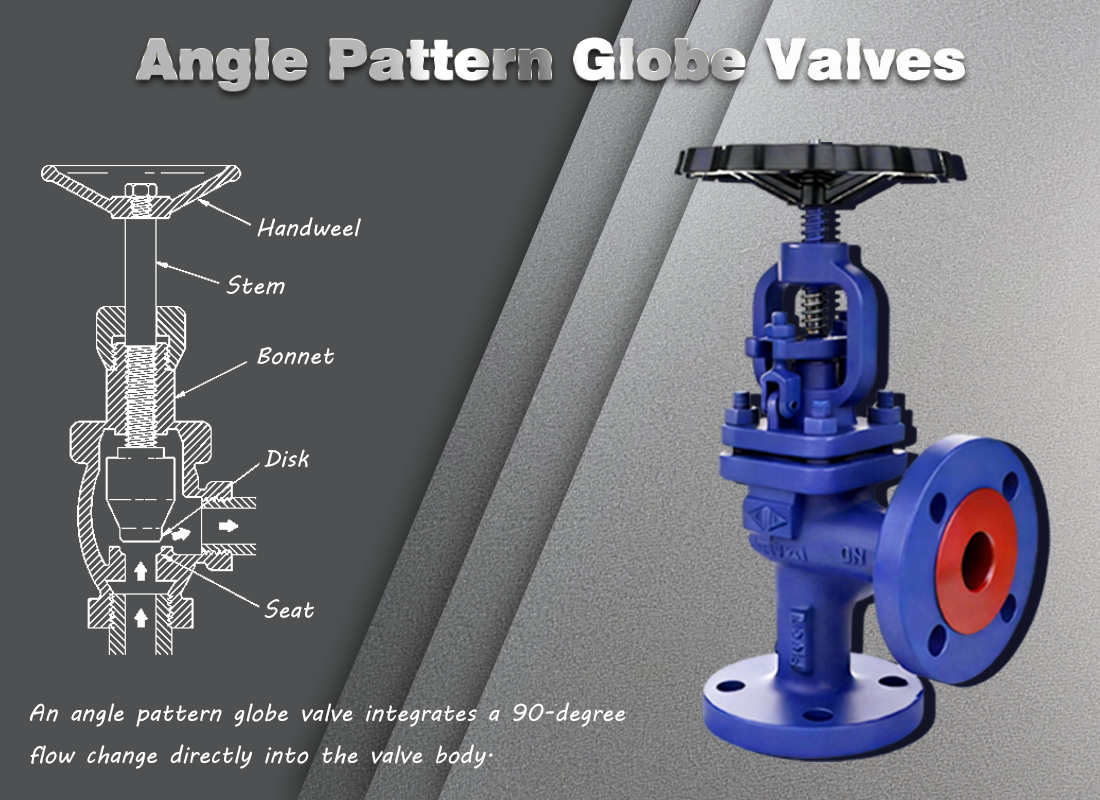

An angle pattern globe valve integrates a 90-degree flow change directly into the valve body. For engineers, this means one component can replace both a valve and an elbow.

This structural advantage is especially valuable in tight installations. Fewer elbows result in fewer welds and connections, improving long-term reliability. In high-temperature or high-pressure services, reducing even one weld can significantly enhance system safety.

From a fluid dynamics perspective, straight pattern globe valves offer more symmetrical internal flow paths. Although globe valves are not low-pressure-drop valves, their pressure loss characteristics are relatively predictable.

Angle pattern globe valves concentrate flow direction changes within the valve body. While this reduces external piping complexity, it can introduce slightly higher localized pressure drop under high flow velocity conditions. Engineers must balance external piping simplification against internal flow resistance during system design.

Straight pattern globe valves are often easier to service due to their balanced internal structure and familiar maintenance procedures. Valve disc, seat, and stem alignment tends to remain stable over long operating periods.

Angle pattern globe valves require more compact internal layouts, which may demand higher maintenance skill levels. However, fewer elbows and welds in the system often result in lower overall maintenance frequency, a key advantage in continuous operation environments.

When space is available and pressure drop control is critical, straight pattern globe valves remain a reliable option. In dense installations or systems requiring frequent direction changes, angle pattern globe valves can significantly simplify piping layouts.

Many experienced engineers combine both designs within the same project, selecting each based on local piping constraints and system function. This practical flexibility is what defines effective piping design.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap