Dec 19, 2025

A check valve, also known as a one-way valve, is one of the most fundamental yet essential components in fluid control systems. Its function is simple but critical: it allows fluid to flow in only one direction and automatically blocks reverse flow. When flow attempts to reverse, the valve closes instantly, preventing backflow that could damage equipment or disrupt system stability.

Because this function is achieved without external power or control signals, check valves are widely used in pneumatic systems, water treatment, steam lines, chemical processing, and many other industrial applications.

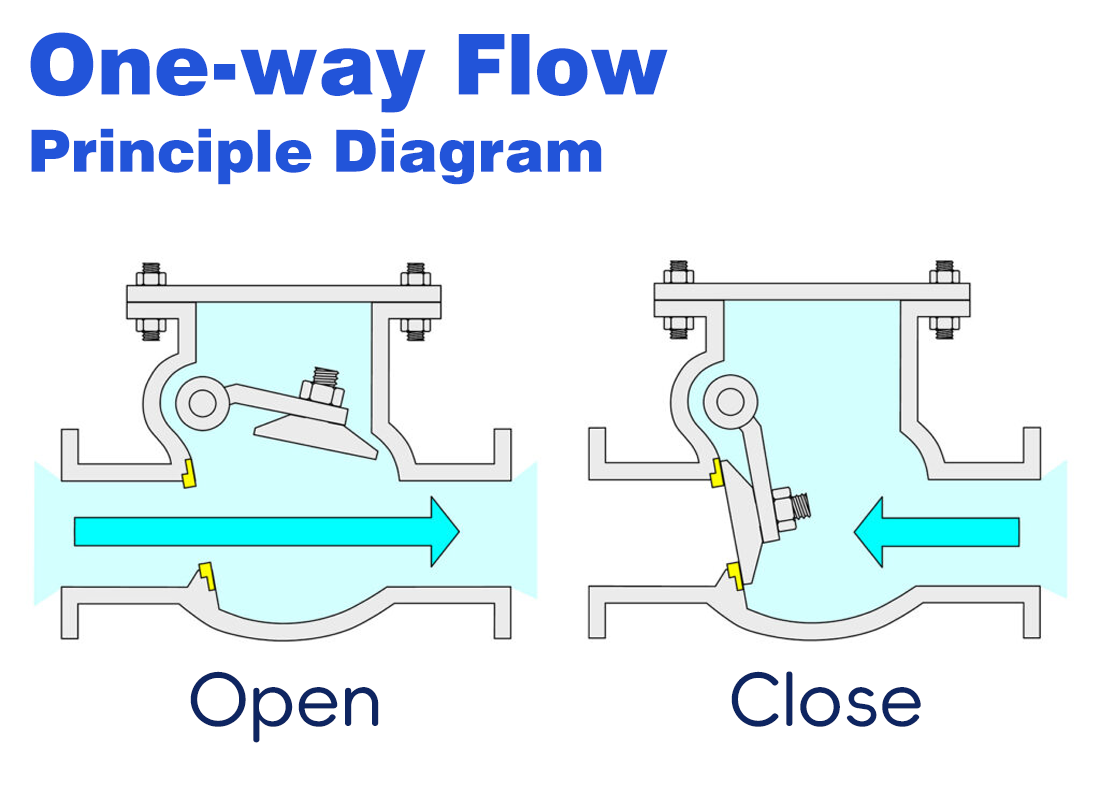

Regardless of design, all check valves rely on the same operating principle: pressure differential created by the fluid itself. When fluid flows in the intended direction, inlet pressure pushes the internal sealing element—such as a disc, poppet, or plate—away from the seat, allowing flow. When the pressure drops or reverses, gravity, spring force, or reverse pressure forces the sealing element back onto the seat, closing the flow path.

This automatic response makes the check valve a passive yet highly reliable safety component, particularly in systems where backflow could cause contamination, pressure surges, or mechanical failure.

Based on internal structure and installation style, check valves are available in several designs. Referring to the CV100–CV600 series, the most common types include the following.

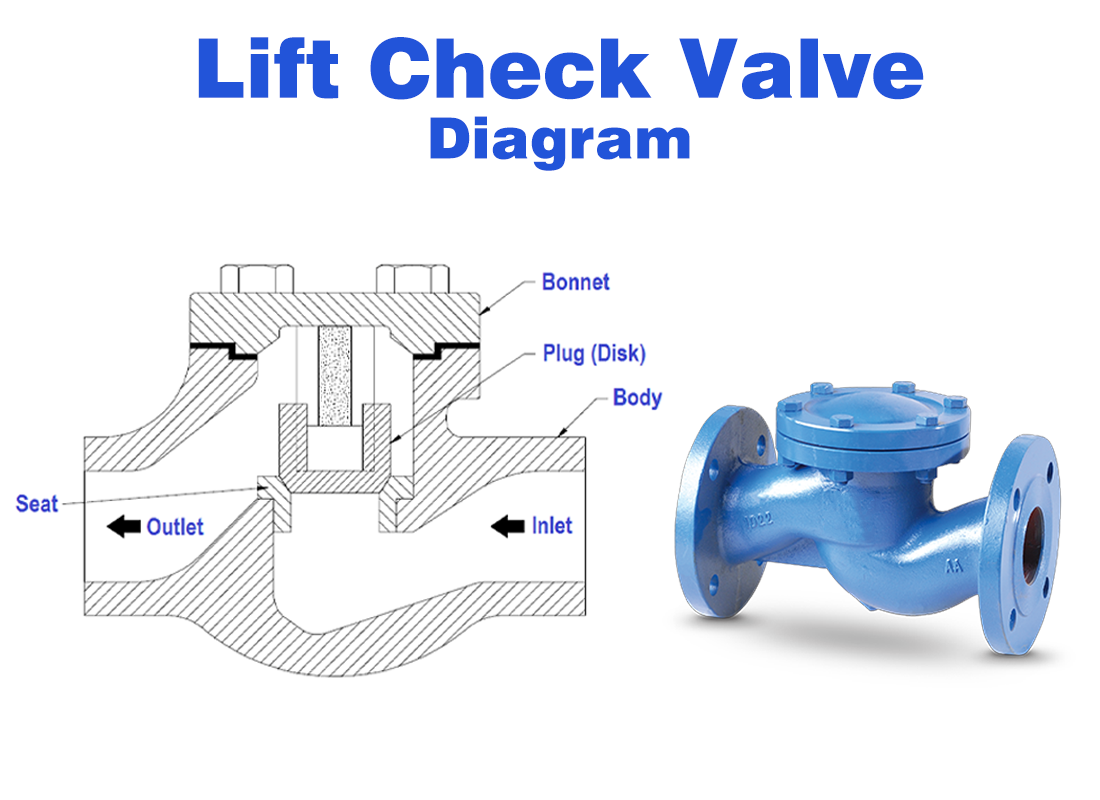

Lift check valves operate by vertical movement of the valve disc. Forward flow lifts the disc off the seat, while reverse flow causes it to drop back into position. This design offers stable sealing performance and is well suited for applications involving water, oil, air, and other general-purpose media.

Lift check valves are often chosen when leakage control is a priority, especially in medium-pressure systems.

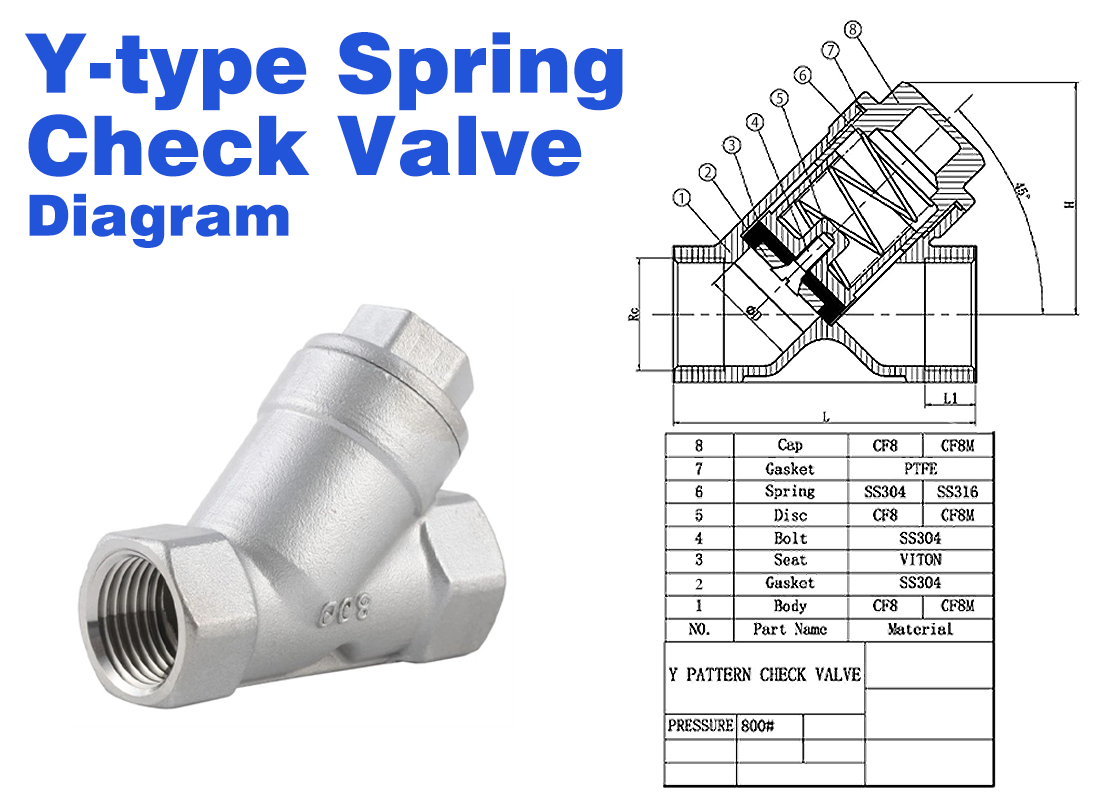

Y-type check valves use an angled flow path combined with a spring-loaded disc. The spring ensures quick closing even under low-pressure conditions, reducing the risk of sudden backflow. The angled body design also helps lower pressure loss compared to straight lift-type valves.

These valves are commonly used in pneumatic and process control systems where frequent cycling and fast response are required.

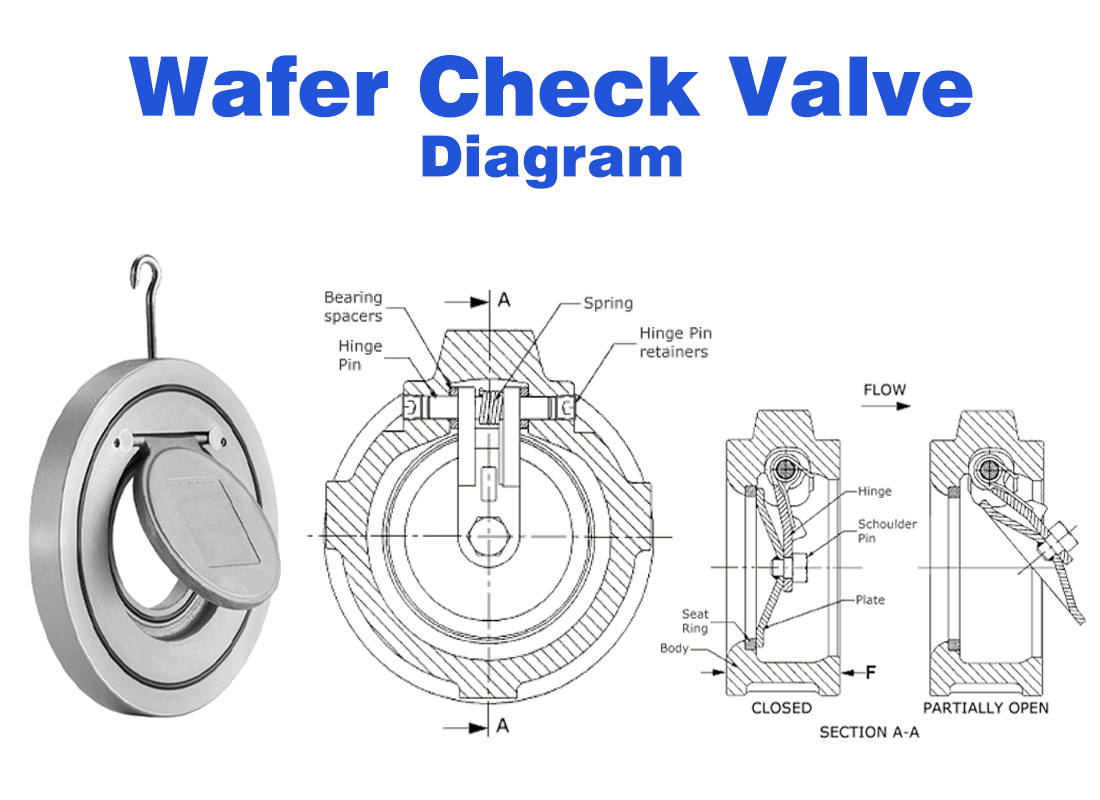

Wafer check valves feature a compact, lightweight design installed between two flanges. The internal plate or dual-disc mechanism opens with forward flow and closes rapidly when flow reverses. Due to their slim profile, wafer check valves are ideal for large-diameter pipelines or installations with limited space.

They are widely used in industrial fluid networks where installation flexibility and reduced weight are important.

Choosing a check valve involves more than selecting a nominal size. Different designs vary in response speed, pressure loss, installation orientation, and maintenance requirements.

Fluid characteristics also play a major role. Media containing particles or debris benefit from smoother internal flow paths that reduce the risk of sticking, while high-temperature or corrosive applications demand careful material and sealing selection.

| Check Valve Design | Working Mechanism | Pressure Loss | Response Speed | Installation Orientation | Typical Applications |

|---|---|---|---|---|---|

| Spring Check Valve | A spring forces the valve to close when flow stops or reverses | Low to medium | Fast | Any direction | Pneumatic systems, compact machinery, vertical piping |

| Lift Check Valve | Flow lifts the disc upward; gravity or back pressure closes it | Medium | Medium | Horizontal only | Clean fluids, steam, general industrial pipelines |

| Swing Check Valve | Disc swings open with flow and closes by gravity | Low | Slow | Horizontal or vertical (upflow) | Water supply, large-diameter pipelines |

| Ball Check Valve | Flow pushes a ball away from the seat; reverse flow forces it back | Medium | Fast | Any direction | Fluids with particles, wastewater, cutting fluids |

| Poppet Check Valve | Guided poppet ensures precise axial movement | Low | Very fast | Any direction | High-cycle pneumatic and hydraulic circuits |

In pump outlets, compressed air mains, steam systems, or parallel pipelines, reverse flow can cause severe damage or system instability. A check valve acts as a silent safeguard—always ready, never dependent on external signals.

Its reliability lies in its simplicity: it responds only to pressure changes, making failure far less likely compared to actively controlled components.

When selecting a check valve, engineers should evaluate medium type, operating pressure, temperature range, installation constraints, and allowable pressure drop. The CV100–CV600 series covers a wide range of structures and sizes, making it adaptable to diverse industrial requirements.

A properly selected check valve does more than prevent backflow—it protects equipment, stabilizes processes, and ensures long-term system reliability, which is ultimately its most valuable role in industrial fluid control.

If you need check valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap