Dec 19, 2025

In industrial automation systems, diaphragm valves are crucial components for controlling fluid flow, and their most critical part is the diaphragm. The diaphragm serves as both a sealing element and a moving part, usually made of rubber, resin, or other flexible materials, making it prone to wear and tear. When the diaphragm is damaged, minor issues may cause small fluid leaks or flow fluctuations, while severe damage can corrode internal valve mechanisms or contaminate the fluid. Proper maintenance and timely diaphragm replacement are therefore essential.

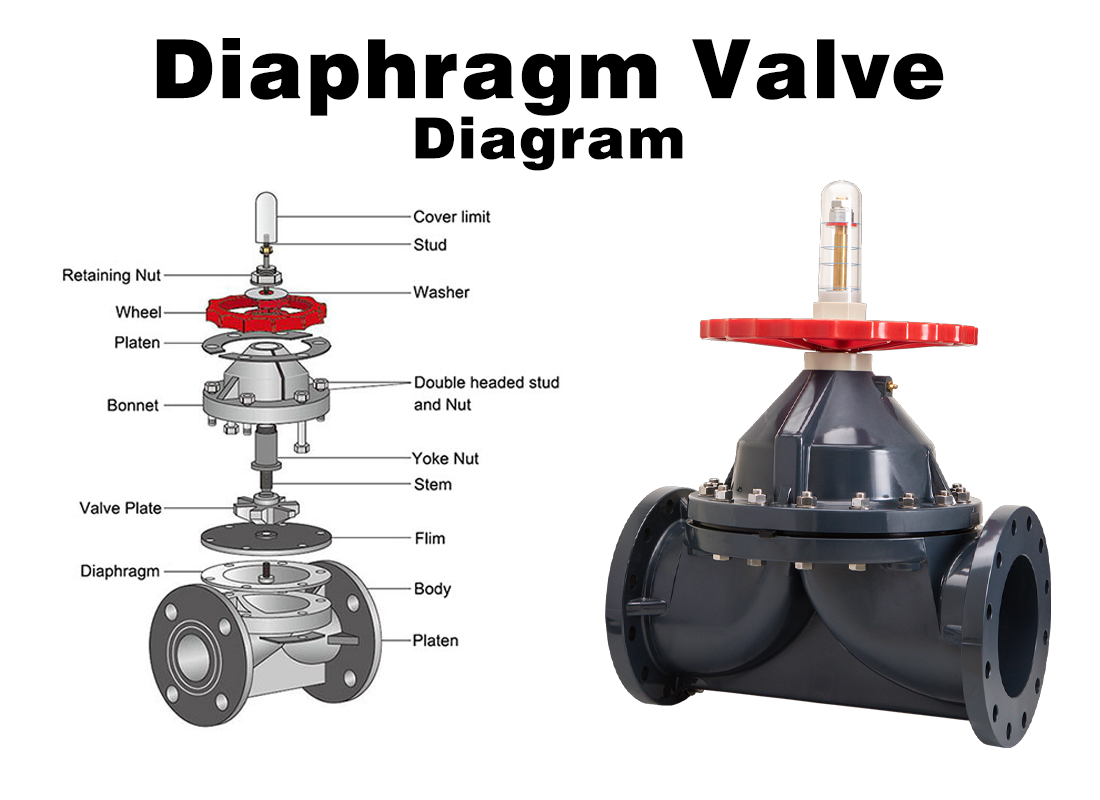

The diaphragm in a diaphragm valve has a dual role: it must tightly seal against the valve seat to prevent leakage while moving up and down with the valve stem to regulate flow. This high-frequency movement, combined with the chemical properties of the fluid, accelerates diaphragm aging. Common causes of diaphragm damage include:

◆ Material fatigue: Frequent valve operation can cause rubber diaphragms to crack or harden.

◆ Chemical corrosion: Long-term exposure to acids, bases, or organic solvents may cause surface swelling or brittleness.

◆ Mechanical wear: Solid particles in the fluid can abrade the diaphragm edges, compromising the seal.

Once the diaphragm is worn or ruptured, valve leakage is inevitable, leading to unstable flow control and potential safety or production issues.

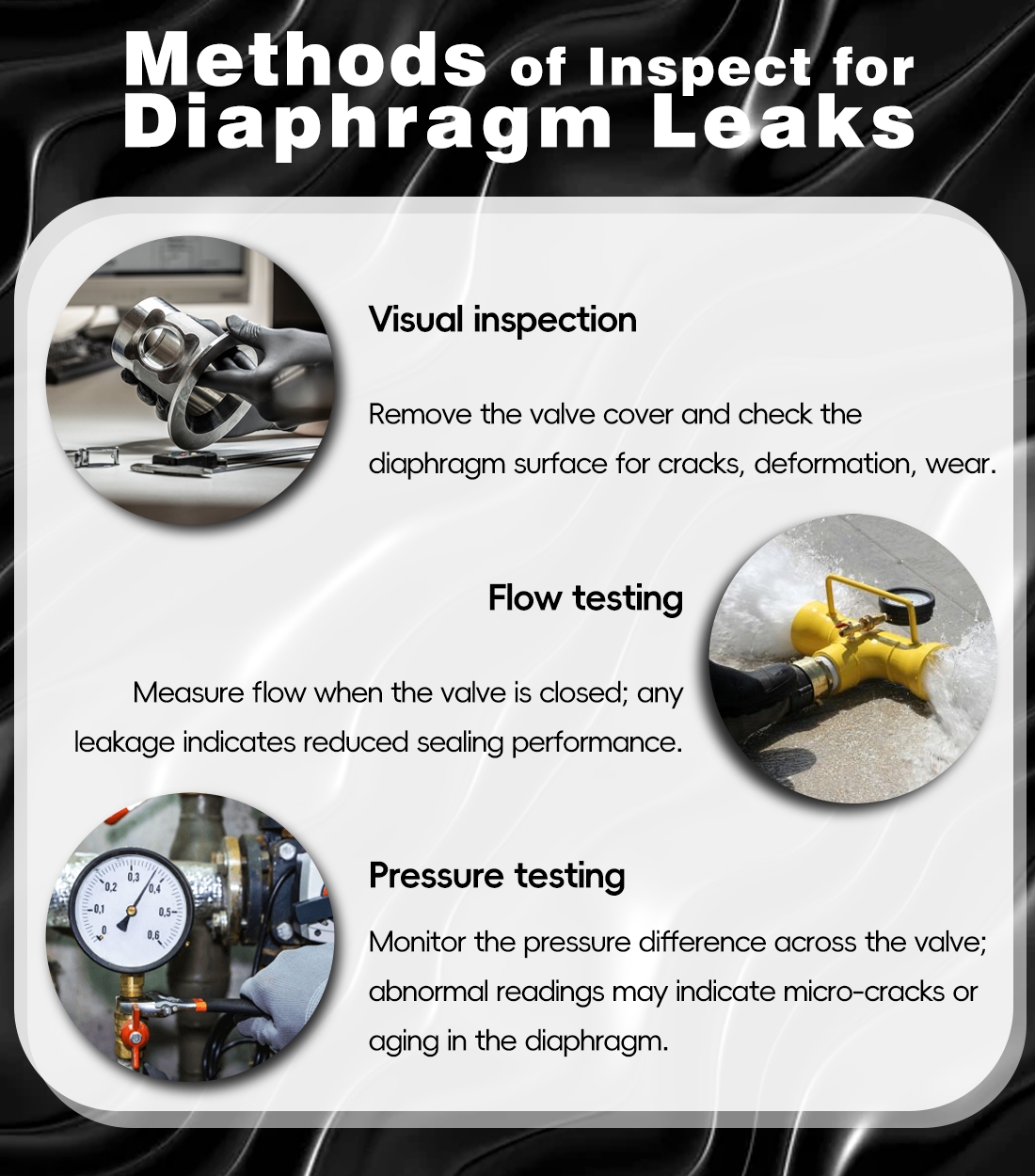

Regular inspection is key to preventing diaphragm valve leaks. Common methods include:

◆ Visual inspection: Remove the valve cover and check the diaphragm surface for cracks, deformation, or wear.

◆ Flow testing: Measure flow when the valve is closed; any leakage indicates reduced sealing performance.

◆ Pressure testing: Monitor the pressure difference across the valve; abnormal readings may indicate micro-cracks or aging in the diaphragm.

These methods are simple and effective, allowing early detection without disrupting production and preventing fluid contamination.

Replacing a diaphragm valve diaphragm is straightforward but requires careful attention:

① Shut down the valve and system pressure: Ensure safety to prevent fluid spray or injuries.

② Remove the valve cover: Loosen bolts carefully and remove the old diaphragm without damaging the valve body.

③ Inspect valve body and seat: Clean out debris and check the seat surface; repair or replace if scratches are found.

④ Install the new diaphragm: Place the diaphragm correctly according to its material and model, ensuring proper contact with the valve seat.

⑤ Reassemble and test: Reinstall the valve cover, gradually apply pressure, and check for leaks to confirm sealing reliability.

When selecting a diaphragm, choose materials suitable for fluid type, operating pressure, and temperature—for example, fluororubber diaphragms resist chemical corrosion, and stainless steel-reinforced diaphragms are suitable for high-pressure applications.

To extend diaphragm life, companies should establish a regular inspection schedule. For continuously operating systems, check diaphragms every 3–6 months. For highly corrosive fluids or fluids containing particles, the inspection interval should be shorter. Additionally, keeping valves clean and preventing long-term accumulation of debris reduces diaphragm wear.

Following proper inspection and replacement procedures not only prevents diaphragm valve leaks from affecting production but also ensures overall stability and safety of the automation system.

If you need diaphram valve, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap