Jan 05, 2026

In steam, hot water, and thermal oil systems, angle seat valves are often exposed to operating temperatures far above ambient conditions. Many field failures do not originate from the valve body itself, but from the gradual degradation of pneumatic actuator performance caused by heat transfer from high-temperature media.

This is why actuator insulation and structural design play a critical role in high-temperature applications.

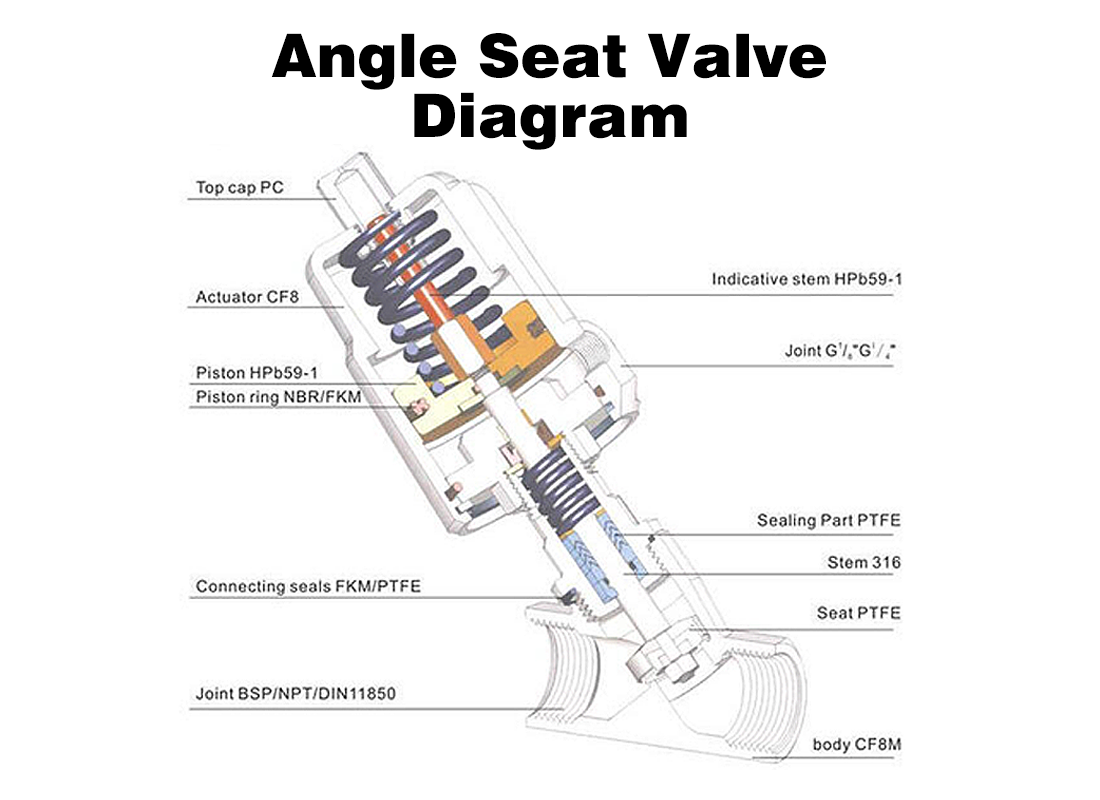

The valve body is in direct contact with hot media, and heat is conducted upward along the valve stem. Without proper insulation or structural buffering, the internal temperature of the actuator increases over time. Pneumatic actuators rely on seals, diaphragms, and lubricated components, all of which are sensitive to heat.

Prolonged exposure leads to seal hardening, reduced elasticity, and slower response. In many cases, the problem develops gradually, starting with delayed actuation and eventually resulting in leakage or actuator failure.

One of the most effective design approaches is the extended valve stem. By increasing the distance between the valve body and the actuator, a natural thermal buffer zone is created. This significantly reduces the amount of heat transferred to the actuator housing.

In steam systems, extended stem designs help maintain actuator components at a more stable temperature, protecting seals and springs from accelerated aging and ensuring consistent performance.

In addition to structural spacing, engineers often use thermal insulation spacers, insulation sleeves, or air gaps to further slow heat transfer. These measures do not completely block heat, but they control the rate of thermal conduction, preventing rapid temperature fluctuations inside the actuator.

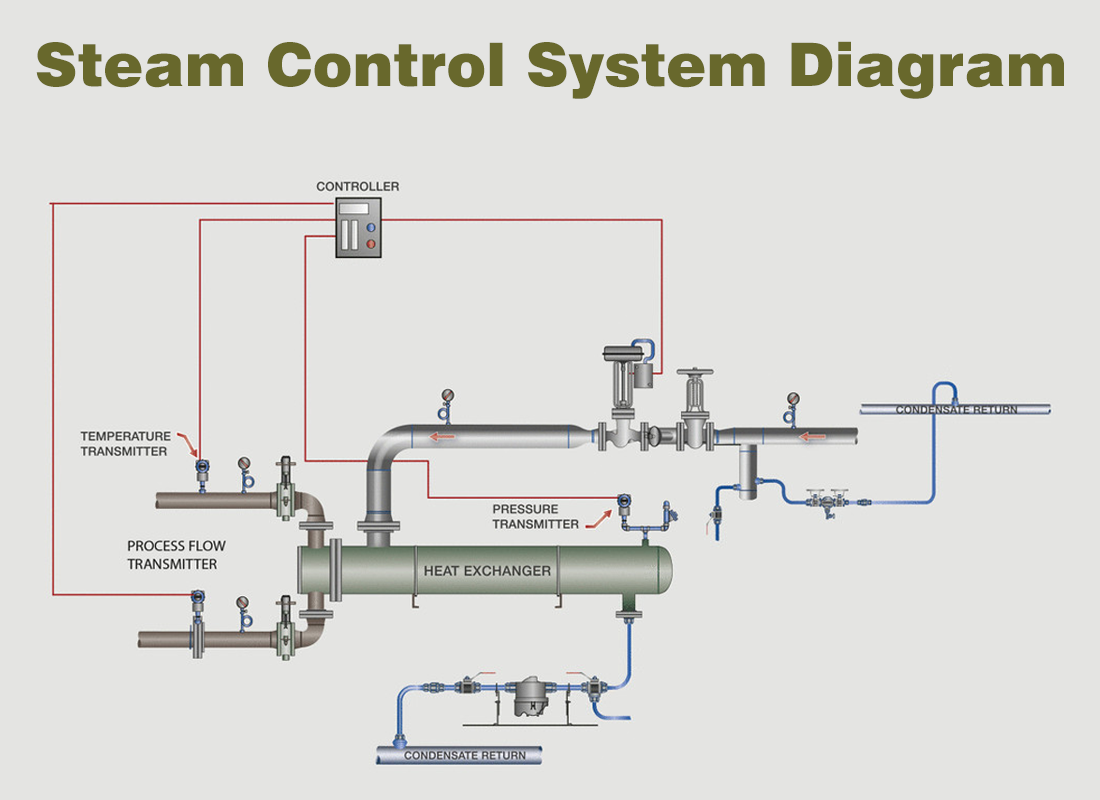

Stable actuator temperature leads to predictable valve response, which is essential for automated control systems.

From a system perspective, insulation design is not just about extending valve life. Actuator failure in high-temperature systems can cause unplanned downtime, especially in continuous steam or process lines. The cost of such interruptions often exceeds the cost of proper valve design.

By incorporating insulation and extended stem designs, angle seat valves maintain reliable operation under high-temperature conditions, reducing maintenance frequency and improving overall system stability.

When selecting angle seat valves for high-temperature media, engineers should evaluate not only the valve body temperature rating, but also the actuator’s thermal environment. Choosing designs with extended stems and insulation features often provides greater long-term reliability than simply oversizing the actuator.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap