Jan 05, 2026

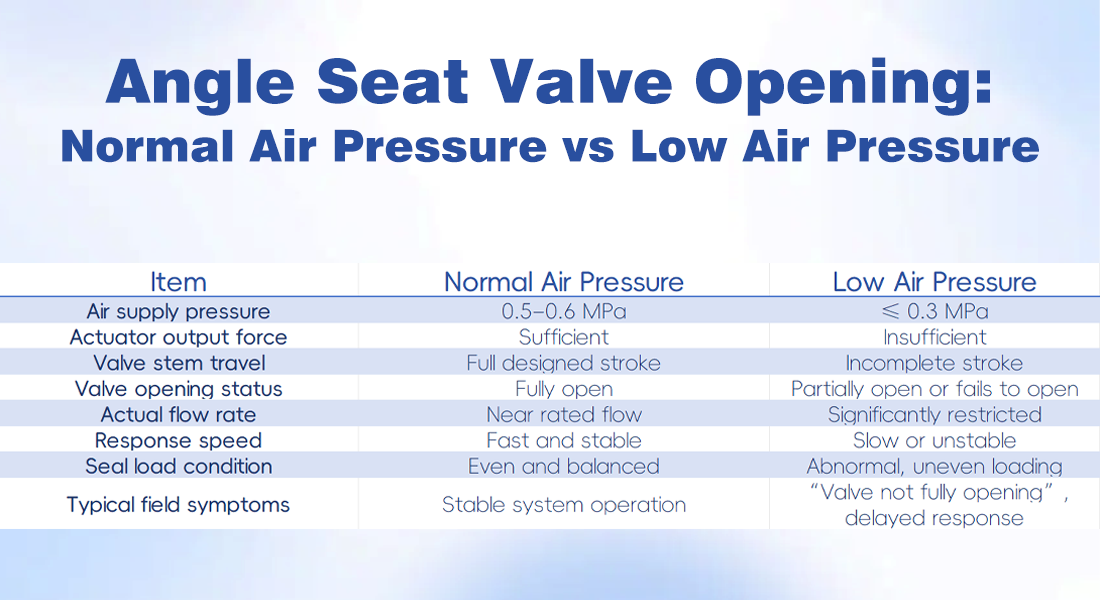

Angle seat valves are widely used in automation systems for their fast response and reliable on-off performance. However, in low-pressure pneumatic systems, engineers often encounter a frustrating issue: the valve responds slowly, opens only partially, or fails to open at all. In most cases, the problem is not a defect in the valve itself, but a mismatch between air supply conditions and actuator capability.

Understanding how angle seat valves behave under low-pressure conditions is essential for proper troubleshooting and selection.

Angle seat valves rely on compressed air to generate actuator force. When the available air pressure is below the actuator’s design range, the output force drops significantly. Even if the solenoid valve switches correctly, the actuator may not receive enough pressure to overcome the valve spring force and process back pressure.

In practice, this often appears as partial movement without full opening, especially when the process medium applies counterpressure on the valve seat.

Standard angle seat valve configurations are typically selected for air supply pressures around 0.5–0.6 MPa. In low-pressure systems operating at 0.3 MPa or lower, using the same actuator size can result in insufficient force to complete the valve stroke.

Actuator force depends not only on pressure, but also on effective piston area. This is why low-pressure applications often require larger actuator diameters rather than changes to the valve body itself.

Angle seat valves use a linear motion design with a defined stroke length. Under adequate pressure, the valve opens quickly and decisively. Under low pressure, however, the final portion of the stroke becomes difficult to complete.

As the actuator force approaches equilibrium with the spring and process forces, movement slows and may stop before full opening. This explains why partial opening is more common than total inactivity in low-pressure conditions.

Although the issue manifests at the angle seat valve, upstream pneumatic components can worsen low-pressure performance. Small solenoid valve orifices, long tubing runs, and restrictive fittings all contribute to pressure loss.

In high-pressure systems, these losses may be negligible. In low-pressure systems, they can determine whether the valve reaches full stroke. Effective troubleshooting therefore requires evaluating the entire pneumatic control system, not just the valve.

For low-pressure applications, actuator selection priorities should shift. Instead of compact size, engineers should focus on available force margin. Larger piston areas and lower minimum operating pressure ratings often deliver better reliability than higher maximum pressure ratings.

Equally important is verifying the valve’s minimum operating pressure, not just its pressure rating. Proper actuator sizing ensures that angle seat valves operate reliably even when air supply pressure is limited.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap