Dec 29, 2025

In compressed air systems, pressure is both a source of power and a hidden risk. When pressure rises beyond safe limits, components can fail quickly and violently. A pneumatic safety valve exists for one purpose only: to prevent that scenario from happening. It does not regulate flow or optimize performance. Instead, it remains inactive until pressure reaches a dangerous level, then responds immediately. To understand why pneumatic safety valves are so reliable, it helps to look closely at how they work and how their internal structure is designed.

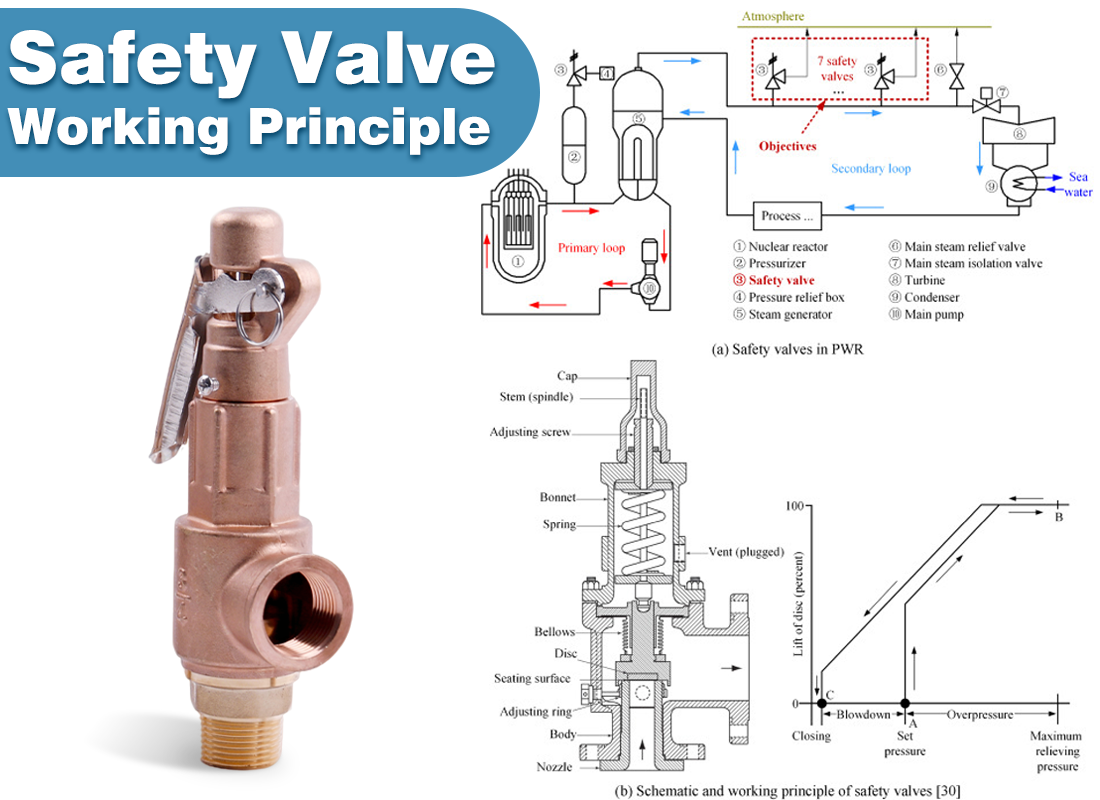

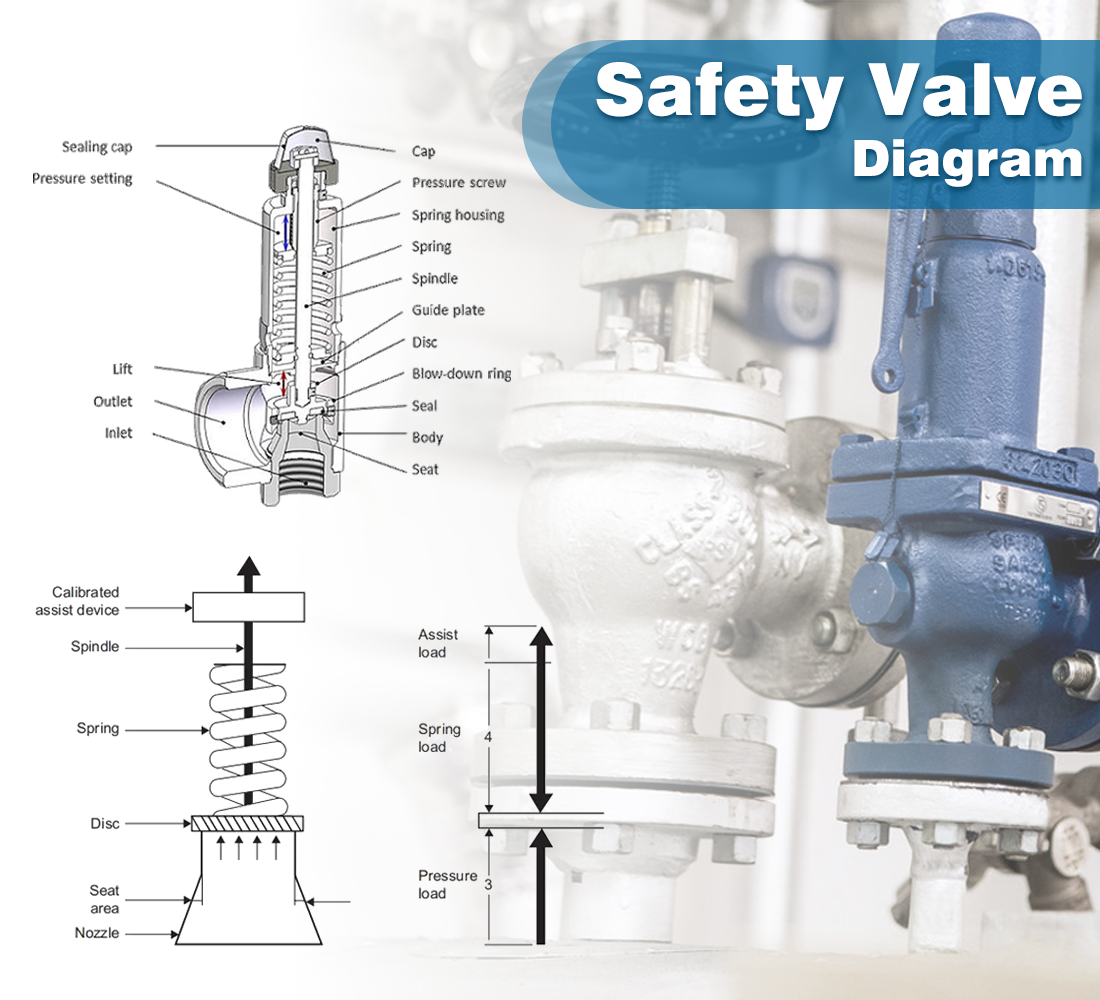

A pneumatic safety valve operates on a simple but highly dependable principle: pressure balance. Under normal operating conditions, the valve stays fully closed, and compressed air does not pass through it. The system pressure acts on the valve’s internal sealing element, but this force is counteracted by a mechanical loading component, typically a spring.

When system pressure rises and exceeds the preset limit, the force generated by the compressed air becomes greater than the spring force. At that moment, the valve opens automatically and releases air to the atmosphere. As pressure drops, the balance of forces shifts again. Once the pressure falls below the set point, the spring pushes the valve closed, restoring the seal without external power, sensors, or control signals.

This purely mechanical response is what makes pneumatic safety valves so dependable, even during power failures or control system malfunctions.

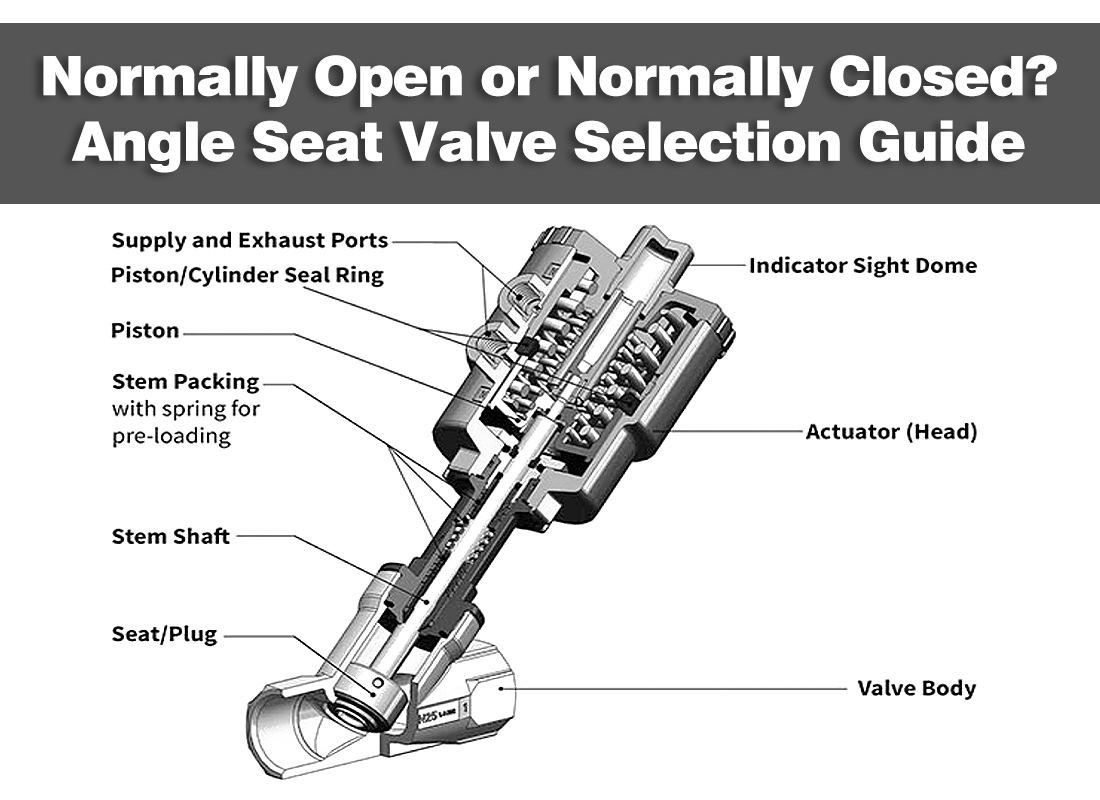

Although pneumatic safety valves appear simple from the outside, their internal structure is carefully designed to ensure fast response and long-term reliability.

The valve body forms the pressure-bearing foundation of the safety valve. Common materials include brass, stainless steel, and aluminum, selected according to pressure level and operating environment. Internally, the body is shaped to provide a direct inlet from the pressure system and a low-resistance outlet for exhaust air.

A smooth and unobstructed flow path is critical. During overpressure events, the valve must release air quickly. Any internal restriction could delay pressure relief and reduce system safety.

The spring is the core element that defines the set pressure of the pneumatic safety valve. By adjusting the spring preload, manufacturers calibrate the pressure at which the valve opens. In some low-pressure or specialized designs, a diaphragm may be used instead of a traditional spring, relying on elastic deformation to trigger valve movement.

Regardless of design, the purpose is the same: to create a stable counterforce against system pressure and ensure repeatable opening behavior.

The valve disc or poppet is responsible for sealing against the valve seat. This sealing interface must remain tight over long periods of inactivity, since safety valves may stay closed for months or years. High-quality sealing materials and precise machining help prevent micro-leakage and ensure reliable operation when needed.

If the sealing surface becomes worn or contaminated, the valve may leak prematurely, leading to unstable system pressure.

As system pressure gradually increases, the upward force acting on the valve disc rises proportionally. Below the set pressure, the spring keeps the valve firmly seated. Once the pressure crosses the threshold, the valve opens quickly, creating a large exhaust opening.

This rapid opening behavior is intentional. A pneumatic safety valve is not designed to modulate flow gradually. Its role is to release pressure decisively, preventing further pressure buildup. As air escapes, system pressure drops rapidly until it falls below the closing pressure, at which point the valve reseats.

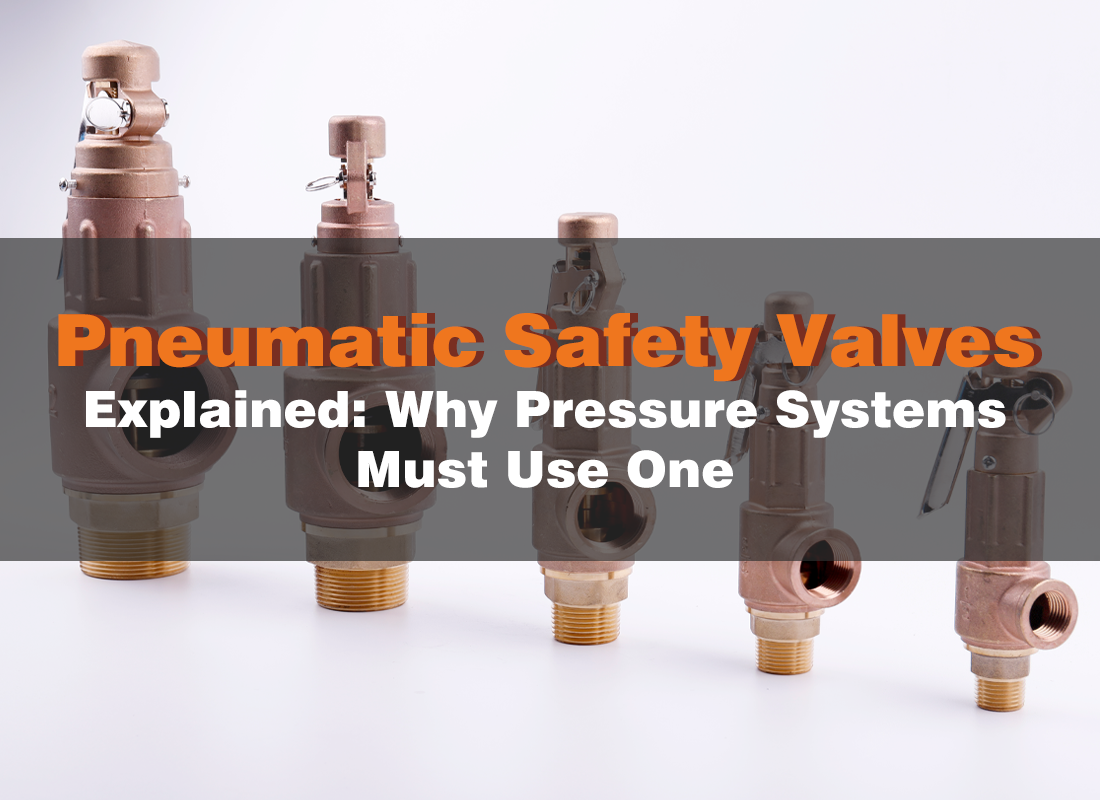

In real-world applications, pneumatic safety valves are often installed on air receivers, compressors, and pressure vessels where they may remain inactive for extended periods. Despite this inactivity, they must function perfectly the instant an overpressure condition occurs.

Internal factors such as spring fatigue, contamination, or poor exhaust design can compromise performance. This is why safety valves typically use simple, robust internal structures with minimal moving parts. Fewer components mean fewer failure points during critical moments.

For systems with frequent pressure fluctuations, the durability of the valve disc and spring becomes especially important. In corrosive or high-temperature environments, material selection for the valve body and seals directly affects service life.

From a design standpoint, the most effective pneumatic safety valves favor direct force transmission and straightforward internal geometry. Complexity rarely improves safety. Instead, reliability comes from proven mechanical principles and careful material selection.

Understanding how a pneumatic safety valve works—and how its internal structure supports that function—helps engineers make better decisions during system design and maintenance. While it may never improve efficiency or throughput, it quietly ensures that compressed air systems remain safe under the most demanding conditions.

If you need safety valves, you can contact us directly.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap