Dec 26, 2025

In any system that operates with compressed air, safety is not optional—it is essential. From air receivers and compressors to various pressure vessels, uncontrolled pressure buildup can lead to serious equipment damage or safety incidents. This is why pneumatic safety valves play a critical role. They are not designed for everyday control but serve as the final line of defense when system pressure exceeds safe limits.

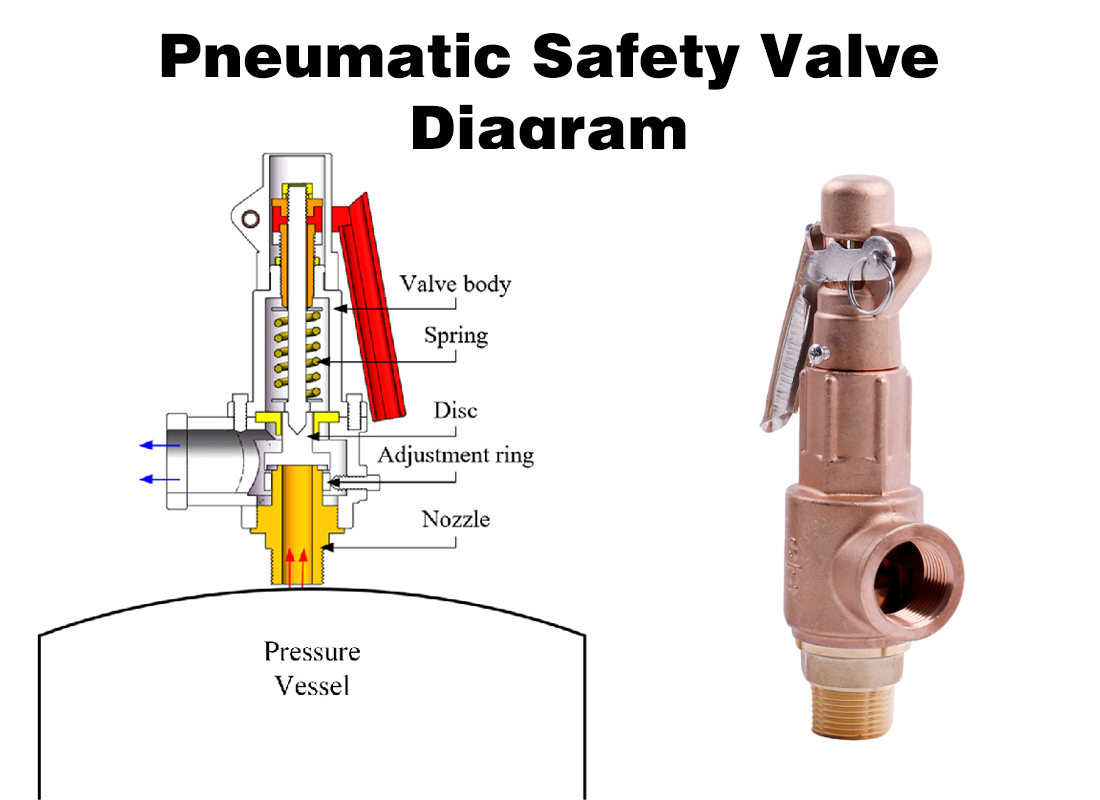

A pneumatic safety valve is a passive pressure protection device. It is typically equipped with a spring-loaded or diaphragm-based mechanism that is preset to open at a specific pressure. Under normal operating conditions, the valve remains closed and does not interfere with the air system.

When internal system pressure rises and exceeds the preset opening pressure, the force of the compressed air overcomes the spring force, causing the valve to open automatically. Excess air is released to the atmosphere, reducing pressure inside the system. Once the pressure drops below the set value, the valve closes again without the need for manual or electrical control.

This simple, self-regulating operation ensures a fast response and high reliability, even during power failures or control system malfunctions.

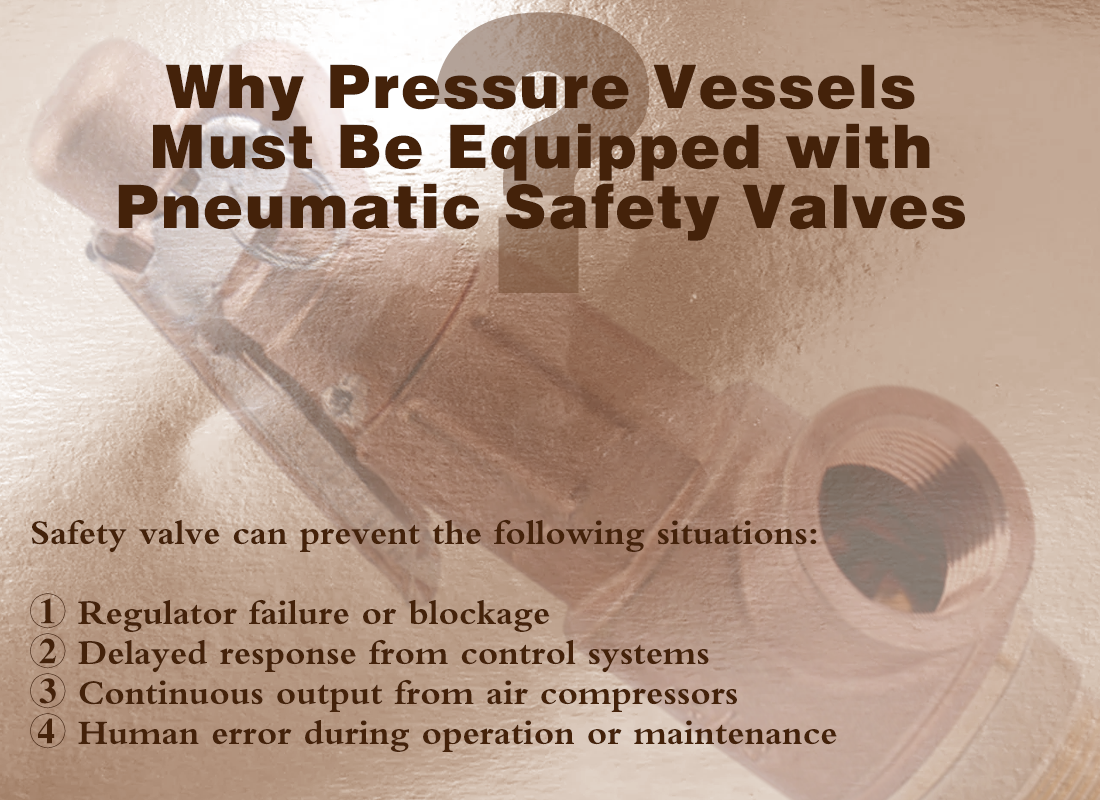

Pressure vessels store energy in the form of compressed air. If pressure is not properly controlled, the consequences can be severe, including vessel deformation, rupture, or explosion. Even when pressure regulators, switches, or control systems are installed, several risk factors remain:

① Regulator failure or blockage

② Delayed response from control systems

③ Continuous output from air compressors

④ Human error during operation or maintenance

A pneumatic safety valve provides mandatory pressure relief when all active control methods fail. For this reason, safety valves are required by most industrial standards and regulations for pressure vessels.

A common example is the air compressor and air tank. Almost every industrial air pump or receiver tank is equipped with a pneumatic safety valve as a standard safety component.

Pneumatic safety valves are installed at points where pressure accumulation poses the greatest risk. Common locations include:

◆ On top or on the side of air receivers

◆ Near the outlet of pressure vessels

◆ Directly on air compressors

◆ At critical high-pressure branches

Proper installation ensures unrestricted exhaust flow. In some applications, mufflers or exhaust pipes may be added to reduce noise or direct released air safely, but they must not restrict the valve’s discharge capacity.

Pneumatic safety valves are sometimes mistaken for pressure regulators, but their functions are fundamentally different.

A pressure regulator is used to maintain a stable working pressure during normal operation. A pneumatic safety valve, however, remains inactive during normal conditions and only opens in abnormal overpressure situations.

Relying on a regulator alone for overpressure protection is risky. If the regulator fails, the system loses its ability to control pressure. A safety valve cannot be replaced by a regulator, and both components should be used together for complete system protection.

Choosing the right pneumatic safety valve requires careful consideration of several factors:

• Set pressure: Slightly above normal operating pressure but below the maximum allowable pressure

• Relief capacity: Sufficient airflow to quickly reduce excessive pressure

• Connection size and mounting type: Compatible with the vessel or piping system

•Operating environment: Consider corrosion, temperature, and contamination

For pressure vessels, reliability and compliance with safety standards are often more important than cost.

From a system design perspective, a pneumatic safety valve does not improve efficiency or control accuracy. Instead, it exists solely to protect equipment and personnel under worst-case scenarios. It is designed for failure conditions, not normal operation.

Whether in large-scale industrial compressed air systems or smaller standalone equipment, any application involving pressure buildup requires a pneumatic safety valve. Its inclusion is not just best practice—it is a fundamental safety requirement.

A pneumatic safety valve may be simple in design, but its role is critical. By automatically releasing excess pressure when preset limits are exceeded and closing once safe pressure is restored, it ensures reliable protection for pressure vessels and pneumatic systems. In any compressed air application, a pneumatic safety valve should never be overlooked or omitted.

If you need safety valves, you can contact us directly.

(FK9025)

Should You Choose DC or AC Solenoid Valve Coils? Features and Selection Guide

Should You Choose DC or AC Solenoid Valve Coils? Features and Selection Guide

Pneumatic Safety Valves Explained: Why Pressure Systems Must Use One

Pneumatic Safety Valves Explained: Why Pressure Systems Must Use One

2-Way Solenoid Valve vs Pneumatic Solenoid Valve: Key Differences and Applications

2-Way Solenoid Valve vs Pneumatic Solenoid Valve: Key Differences and Applications

NAMUR Interface on Angle Seat Valves: Why Actuator Connection Matters

NAMUR Interface on Angle Seat Valves: Why Actuator Connection Matters

Why Certain Applications Require 316L Stainless Steel Valve Bodies

Why Certain Applications Require 316L Stainless Steel Valve Bodies

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap