Jan 14, 2026

A 2-way solenoid valve is widely used in industrial systems for its simplicity and fast response. However, when applied in systems requiring flow regulation, its limitations become evident. Engineers often encounter noise, unstable flow, and premature failure when these valves are forced into modulating duties.

The root cause lies in design intent. A solenoid valve is optimized for fully open or fully closed operation, not for maintaining a stable intermediate position.

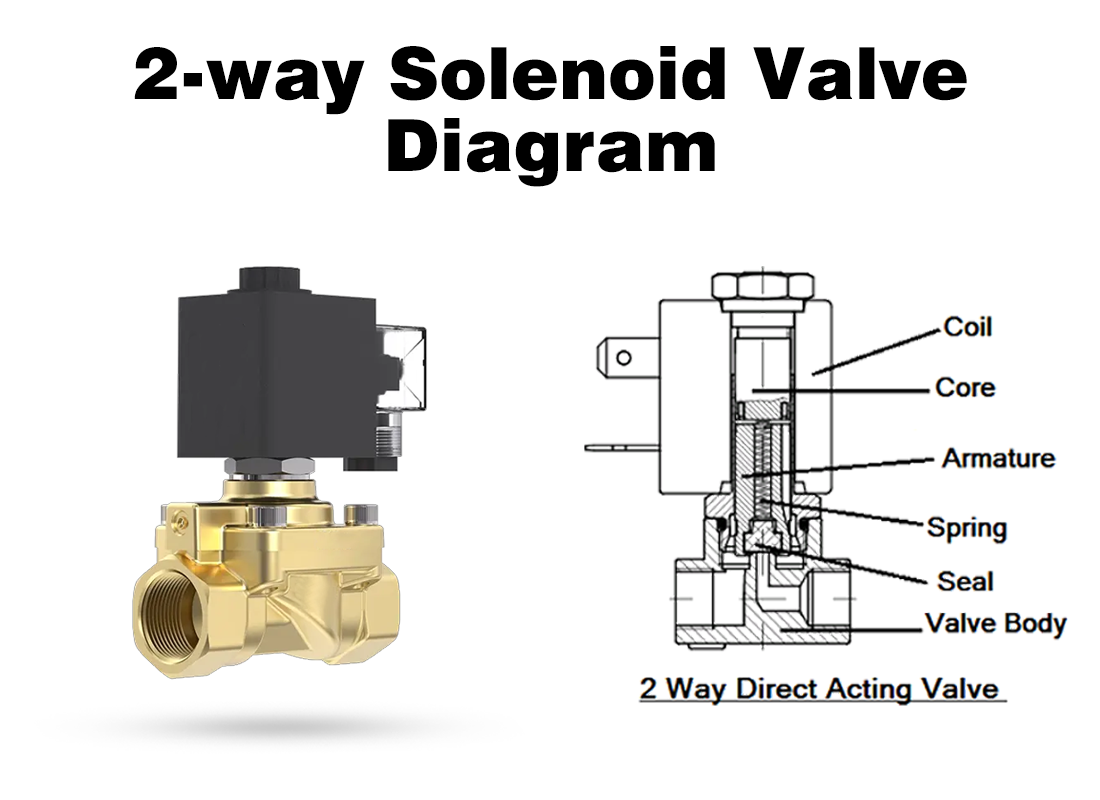

Most solenoid valves for fluid control use a plunger-type mechanism. Once energized, the plunger lifts rapidly, allowing full flow. When de-energized, it closes immediately under spring force. This binary behavior works well for on/off control but lacks the mechanical stability required for modulation.

When held partially open, the plunger experiences uneven forces, leading to vibration and inconsistent sealing.

In many systems, flow regulation is attempted through high-frequency switching controlled by PLCs. While this may achieve short-term flow control, it significantly increases mechanical stress.

Each cycle causes impact between the plunger and valve seat. Over time, seal degradation, guide wear, and reduced magnetic force efficiency occur. In practice, valve lifespan under such conditions is often much shorter than expected.

Operating a 2-way solenoid valve in a partially open position introduces turbulent flow near the orifice. This turbulence generates noise and accelerates erosion of the valve seat.

As erosion progresses, internal leakage becomes more likely. These failures often develop gradually, making them difficult to detect until system performance is affected.

True modulation requires a predictable relationship between valve position and flow rate. Standard solenoid valves lack linear stroke characteristics, making precise control difficult.

Alternatives such as proportional solenoid valves or control valves are designed with balanced forces and optimized flow paths, ensuring stable performance under partial opening conditions.

While a 2-way solenoid valve remains a reliable solution for simple on/off control, forcing it into modulating service increases wear and reduces system reliability. Choosing a valve designed for modulation is often the more economical and stable solution in the long run.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap