Jan 28, 2026

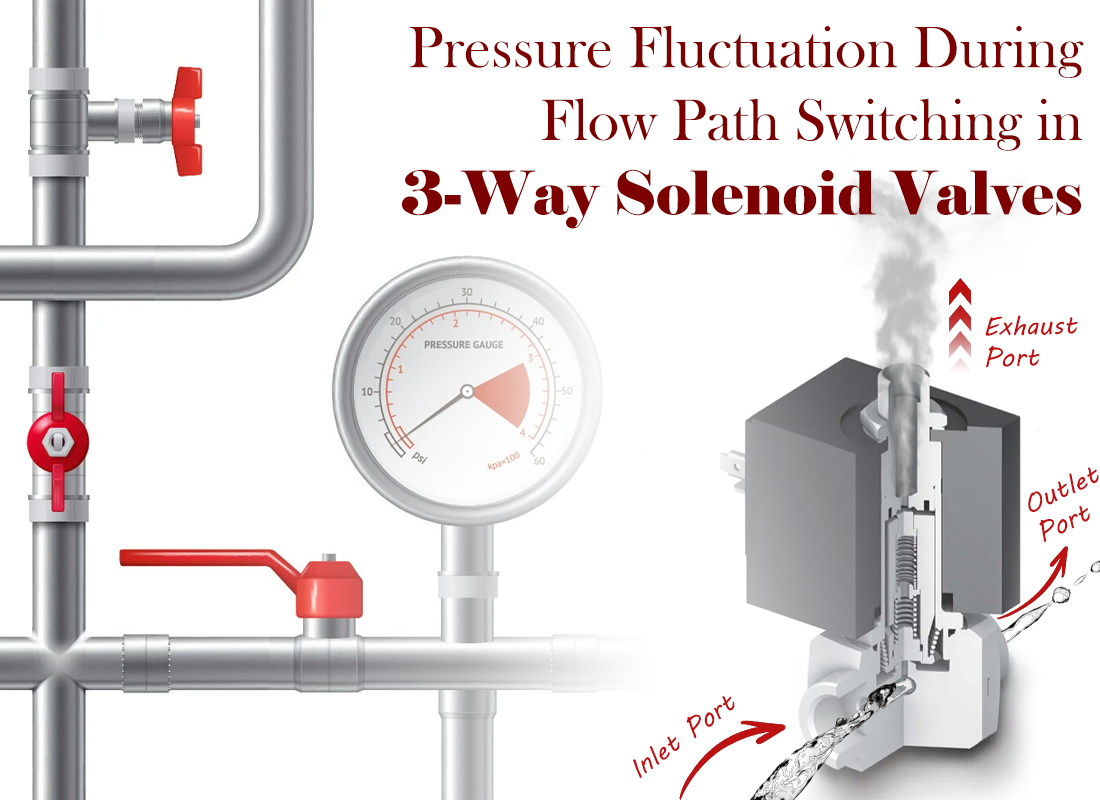

In pneumatic and fluid control systems, a 3 way solenoid valve is commonly used to alternate between supply and exhaust paths. At the moment of switching, the previously stable flow condition is abruptly disrupted. Pressure, velocity, and flow direction change almost simultaneously, often causing noticeable pressure fluctuations within the system.

These effects are not defects, but inherent characteristics of how a solenoid valve 3 way manages multiple flow paths.

When a 3-way solenoid valve switches from pressurization to exhaust, stored energy in the system is released within milliseconds. The reverse action—reapplying pressure to a previously vented line—creates another sharp transient.

In compressed air systems, gas compressibility amplifies these effects. In liquid or mixed-media systems, fluid inertia and line stiffness can further intensify the pressure response. This is why a 3 way air solenoid valve operating at high cycling frequency often shows more pronounced pressure instability.

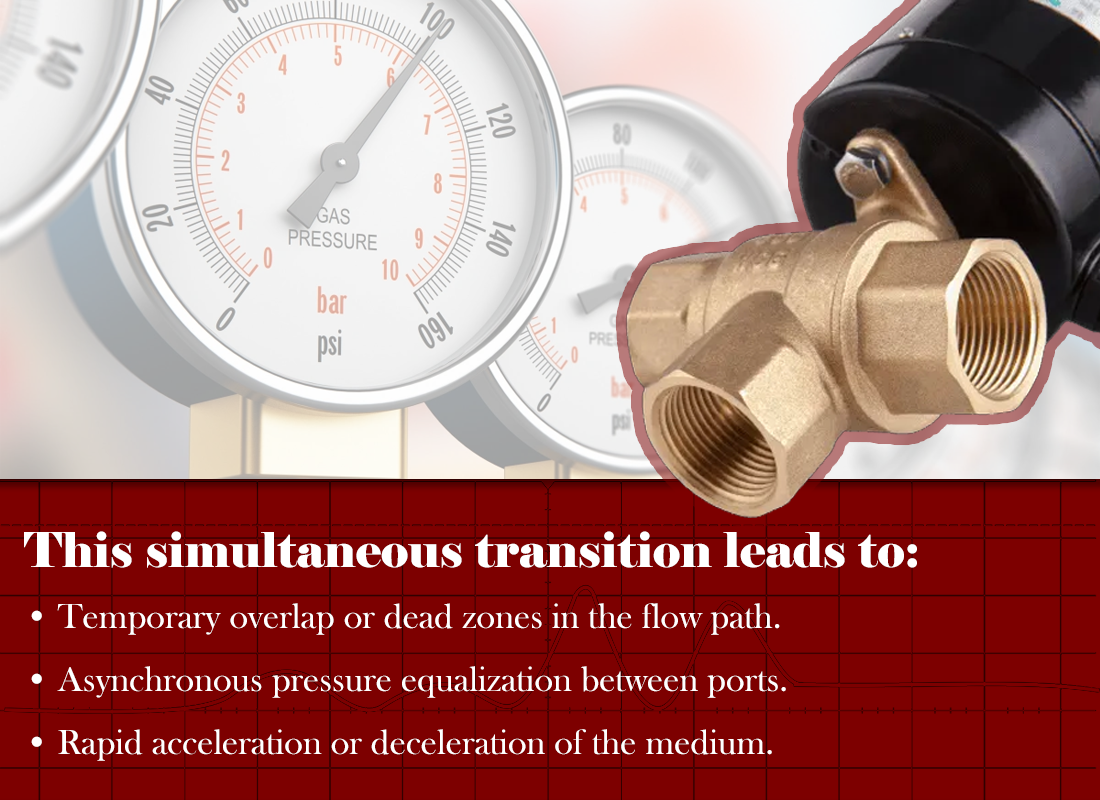

Compared with a two-port valve, the difference between 2 way & 3 way solenoid valve design is fundamental. A two-way valve only opens or closes a single flow path. A three-way valve must close one port while opening another during the same actuation.

In a 3 way 2 position solenoid valve, these transitions occur quickly, making pressure spikes more noticeable than in two-way designs.

The internal mechanism of a valve solenoid 3 way plays a critical role. Direct-acting designs respond quickly but tend to create sharper flow changes. Pilot-operated structures introduce a staged response, which can reduce the intensity of pressure fluctuation.

For a 3 way normally closed solenoid valve, the exhaust phase during de-energization can also generate localized pressure drops or reverse flow, particularly near actuators.

| System Type | Observed Effect |

|---|---|

| Pneumatic automation | Momentary pressure spikes |

| Multi-valve manifolds | Combined pressure oscillation |

| High-speed machinery | Increased vibration and noise |

| Precision control systems | Reduced positioning stability |

When multiple 3 way solenoid valves switch simultaneously, these transient effects can accumulate and propagate through the system.

To manage pressure fluctuation effectively, engineers should look beyond nominal flow rates. Key considerations include:

◆ Internal flow path smoothness

◆ Switching speed and stroke profile

◆ Use of damping or flow-restricting components

◆ Line volume and downstream compliance

Selecting a 3 way solenoid valve diagram that matches the control logic of the system often improves stability more than simply increasing valve size.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap