Jan 27, 2026

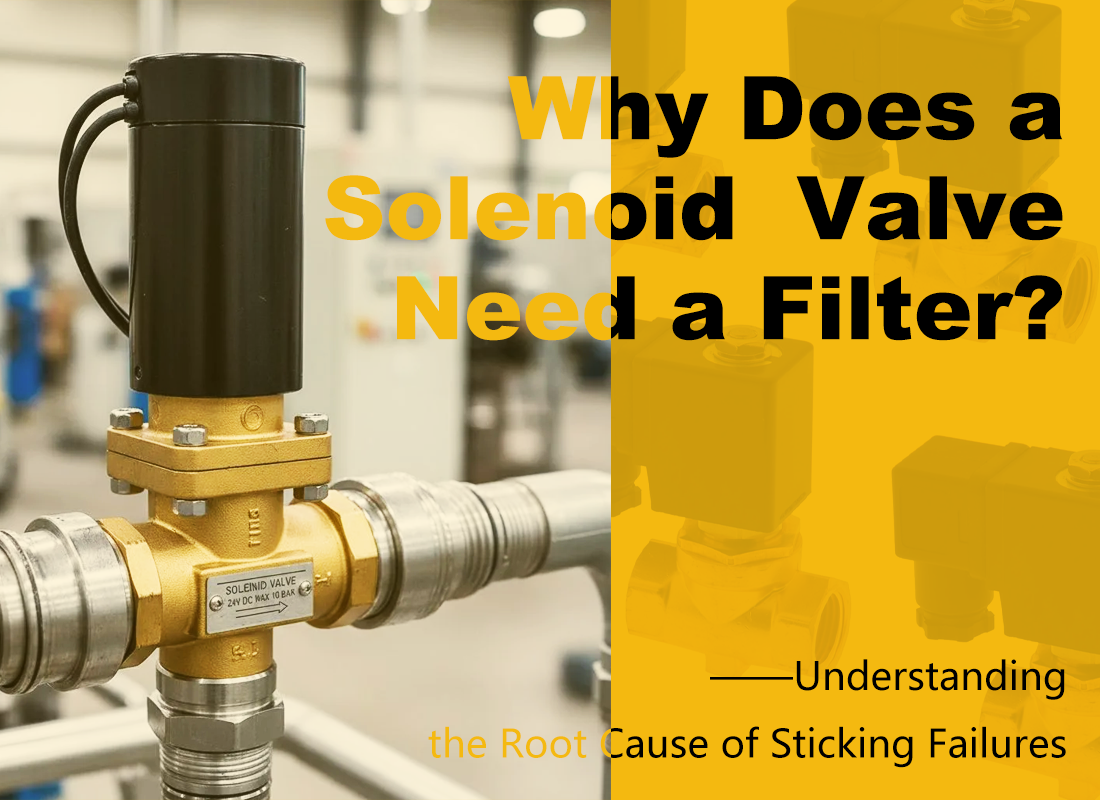

In real industrial environments, a 2-way solenoid valve rarely operates with perfectly clean media. Whether in compressed air, industrial water, or hydraulic oil systems, contaminants such as particles, rust, oil residue, or condensate are almost unavoidable. Due to the compact internal design of a solenoid valve 2 way, these impurities tend to directly affect the valve core and sealing surfaces.

A key characteristic of 2-way solenoid valves is their reliance on electromagnetic force to drive a short-stroke, linear valve core. The clearance between the core, guide sleeve, and sealing surface is extremely small. This precision makes the valve highly efficient—but also vulnerable when contamination enters the flow path.

In many industrial solenoid valve applications, insufficient filtration allows impurities to reach the valve body, where narrow flow passages prevent particles from passing through freely.

Once contaminants enter a normally closed solenoid valve, they typically cause problems in three ways: increased friction along the guide, damage to sealing surfaces, or interference with the return spring. Over time, these effects lead to sticking, leakage, or unstable switching—especially in pneumatic and hydraulic systems.

| Medium Type | Common Impurities | Main Risk to Valve Core | Typical Result |

|---|---|---|---|

| Compressed Air | Rust, oil mist, condensate | Increased friction | Delayed response |

| Industrial Water | Sand, scale, corrosion debris | Seal damage | Continuous leakage |

| Hydraulic Oil | Sludge, metal particles | Core sticking | Incomplete switching |

In a pneumatic solenoid valve, contamination often results in delayed response rather than immediate failure. In contrast, a hydraulic solenoid valve may suffer from continuous leakage or incomplete switching, even under moderate contamination levels. For any fail safe solenoid valve, compromised sealing undermines its core safety function.

Selecting a 2 way solenoid valve without considering media cleanliness is a common engineering mistake. Proper filtration, suitable sealing materials, and realistic maintenance planning are often more critical than coil voltage or port size alone.

Understanding how impurities interact with compact valve structures allows engineers, distributors, and end users to reduce downtime, extend service life, and maintain consistent system performance.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap