Jan 20, 2026

In automated fluid systems, using multiple solenoid valves in parallel is common practice. Whether in multi-branch water distribution, pneumatic manifolds, or synchronized machine stations, engineers often focus on whether each valve operates correctly on its own. What is frequently underestimated is how simultaneous valve actuation affects overall system stability.

| Risk Factor | System Impact | Engineering Consideration |

|---|---|---|

| Simultaneous valve opening | Sudden pressure drop | Staggered control signals |

| Pressure fluctuation | Incomplete valve actuation | Check minimum operating pressure |

| Flow instability | Noise and vibration | Optimize pipeline layout |

| Repeated pressure shock | Seal wear and leakage | Select suitable valve structure |

When several solenoid valves receive the same control signal, they tend to open or close at nearly the same moment. From a control standpoint, this looks efficient. From a physical standpoint, however, it introduces a sudden increase in flow demand.

This can lead to noticeable pressure fluctuation, especially in systems where supply capacity or pipe sizing leaves little margin.

Every solenoid valve relies on a balance between electromagnetic force, spring force, and medium pressure. When multiple valves open simultaneously, the upstream pressure may drop temporarily. In pneumatic systems, this often results in slower response or incomplete opening. In liquid systems, turbulence and transient noise are common side effects.

Such conditions increase wear on valve seals and shorten service life.

Rather than relying solely on hardware upgrades, many engineers improve system reliability through smarter control logic. Staggered actuation, where valves open in a predefined sequence with short delays, significantly reduces peak demand.

This approach stabilizes system pressure without affecting overall cycle time in most applications.

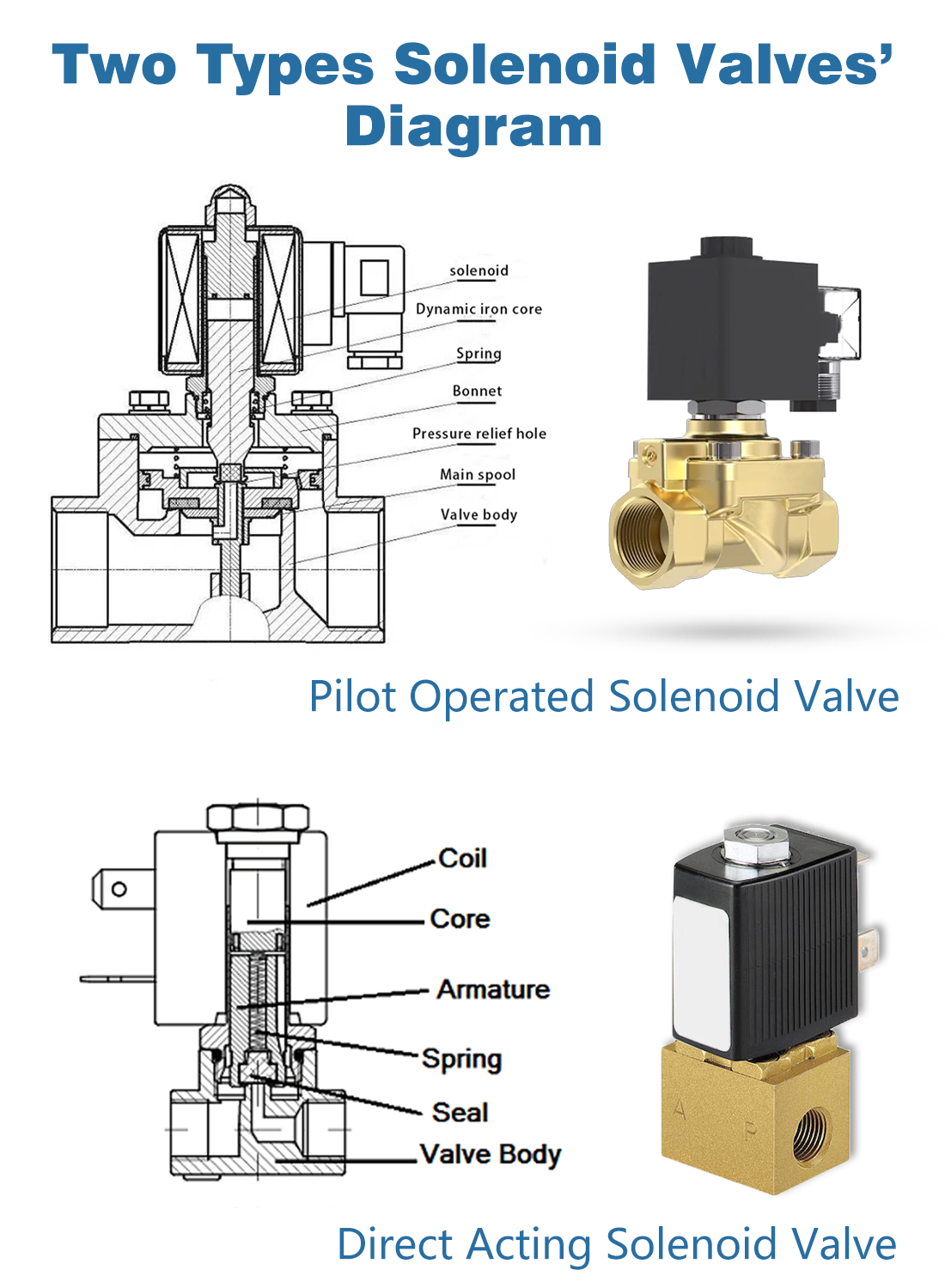

Valve type matters more in parallel configurations. A pilot operated solenoid valve depends on sufficient pressure differential to function correctly. During pressure dips caused by simultaneous opening, pilot valves are more likely to fail or respond unpredictably.

A direct acting solenoid valve, while limited in flow capacity, maintains consistent operation under low or fluctuating pressure, making it suitable for multi-valve control systems with small flow rates.

Experienced engineers view parallel solenoid valves as part of a dynamic system, not isolated components. Factors such as flow control strategy, pressure stability, and valve response time must align.

In many cases, improving coordination between valves is more effective than increasing coil power or upsizing the valve body.

For distributors and procurement teams, recognizing these control-related issues helps avoid unnecessary product replacements. Many reported solenoid valve failures in parallel systems are rooted in control logic design, not manufacturing defects.

Addressing these issues early leads to more stable systems, longer valve life, and fewer service interventions.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap