Jan 26, 2026

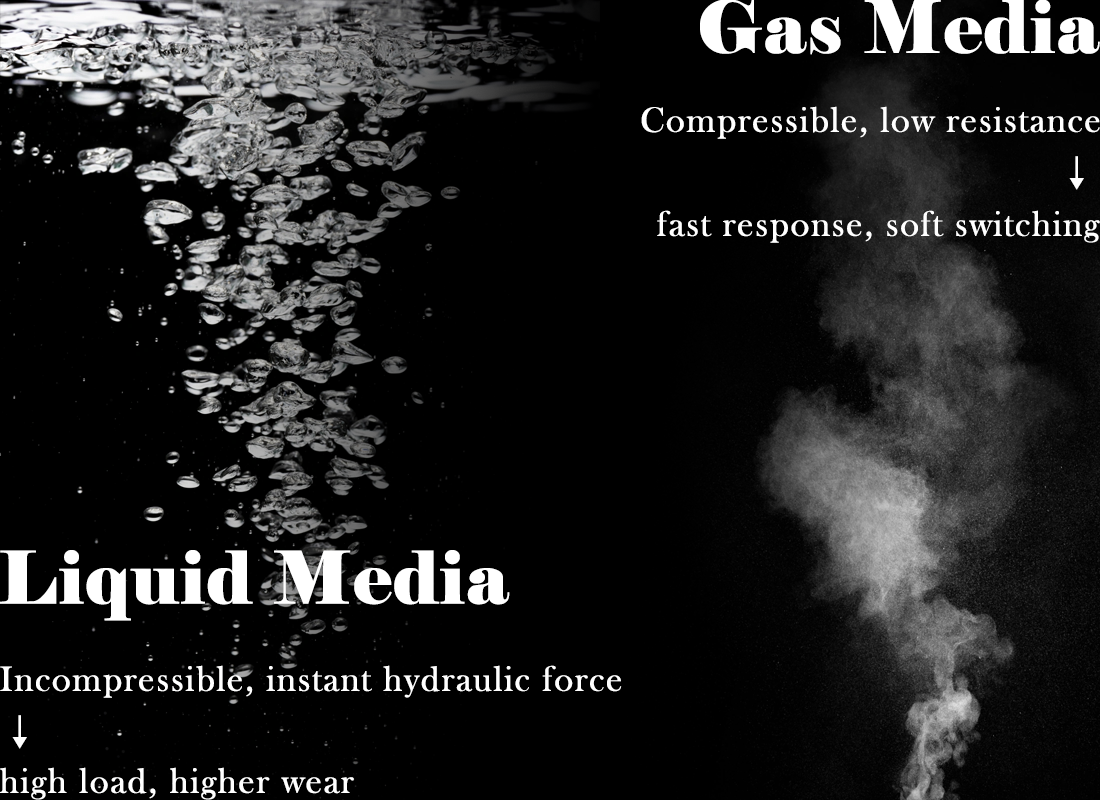

In industrial automation, a 2 way solenoid valve is often selected based on pressure rating and port size, while the working medium is treated as a secondary concern. In practice, gas and liquid behave very differently inside the valve body. Differences in density, compressibility, and flow inertia directly influence response speed, sealing behavior, and long-term reliability.

A valve that performs smoothly in compressed air may show delayed closing or unstable sealing in water or oil. Understanding these differences helps engineers avoid misapplication and ensures stable operation across industrial solenoid valve applications.

Gas media are highly compressible and have low density. When a 2-way solenoid valve opens, the pressure equalizes gradually, allowing the valve core to move with relatively low resistance. This explains why 2 way pneumatic solenoid valve systems often exhibit fast response and soft switching.

Liquid media, by contrast, are nearly incompressible and much denser. Once energized, the valve core must overcome immediate hydraulic force. In a solenoid valve 2 way handling liquids, pressure changes translate directly into mechanical load on the plunger and sealing surfaces, increasing wear if not properly designed.

In gas applications, such as compressed air or inert gases, a normally closed solenoid valve typically opens quickly and consistently. The compressibility of gas cushions the motion of the valve core, reducing impact stress during switching.

This is why 2-way solenoid valves are widely used in pneumatic automation, packaging machinery, and pick-and-place systems. Even with frequent cycling, the valve experiences relatively mild mechanical shock, extending coil and seal life under proper operating conditions.

Liquid systems present a different challenge. In water, oil, or hydraulic fluids, the same 2 way solenoid valve reacts more abruptly. The moment the valve opens, flow accelerates instantly, and closing can generate pressure spikes.

In hydraulic solenoid valve safety applications, response speed must be carefully matched to system pressure. Excessively fast closing can amplify fluid hammer effects, while slow response may compromise control accuracy in dosing or cooling circuits.

Gas molecules are small and mobile, which places higher demands on sealing quality. In pneumatic use, minor imperfections in seat geometry or seal compression can result in leakage that is difficult to detect visually.

A fail safe solenoid valve designed for gas service often relies on optimized elastomer selection and surface finish. Even slight seal aging can lead to performance drift, especially in pneumatic safety valve circuits where leakage directly affects system pressure stability.

Liquid sealing is generally more forgiving in terms of leakage detection, but more demanding in mechanical durability. The higher density of liquid media presses the seal firmly against the valve seat, improving initial tightness.

However, over time, repeated high-force contact accelerates seal wear. In a solenoid valve failure modes analysis, liquid systems frequently show issues such as seat deformation, seal extrusion, or sticking caused by contamination carried by the fluid.

Gas flow through a 2 way solenoid valve tends to stabilize quickly after opening due to compressibility. Minor fluctuations in upstream pressure are absorbed by the medium itself, resulting in smoother downstream behavior.

Liquid flow is far less forgiving. Any instability upstream is transmitted directly through the valve, affecting downstream components. This is why flow conditioning and proper sizing are critical when a solenoid valve 2 way is used for liquid control in cooling loops or process dosing systems.

| Medium Type | Response Speed | Sealing Sensitivity | Wear Characteristics | Common Applications |

|---|---|---|---|---|

| Gas | Fast, cushioned | High leakage sensitivity | Low mechanical wear | Pneumatic automation, air control |

| Liquid | Immediate, rigid | Strong initial sealing | Higher seal wear | Cooling systems, fluid dosing |

For distributors and equipment designers, selecting a 2 way solenoid valve should always begin with medium identification. A valve optimized for air may not be suitable for water or oil without modification.

In mixed-media systems, engineers often choose reinforced seals, adjusted spring force, or damped plunger designs to balance response speed and durability. This approach reduces unexpected downtime across industrial solenoid valve applications.

Gas-operated valves generally experience slower seal degradation but require periodic leak checks. Liquid-operated valves demand closer inspection of seals and internal surfaces due to higher mechanical stress.

From a lifecycle perspective, understanding medium behavior helps procurement teams avoid over-specification while ensuring safety margins remain intact, especially when valves function as control or isolation elements in critical circuits.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap